18

EN

–

Maintenance

where all the operations that must

be carried out for correct maintenance are descri-

bed (section dedicated to the maintenance tech-

nician)

–

Recycling and disposal

where all the operations

to be carried out at the end of the unit life are de-

scribed (section dedicated to the owner, installer

and maintenance technician)

The instruction manual must always stored in a pro-

tected and dry place.

The user can request a new manual from the manu-

facturer or from the local retailer if the manual is lost

or damaged. The request must include details of the

filtering section model and the serial number indi-

cated on the identifying data plate.

This manual reflects the technical features at the

date of preparation; the manufacturer reserves the

right to upgrade the production and the subsequent

manuals without being under an obligation to also

update previous versions.

The manufacturer will not be held liable in case of:

– improper use or misuse of the filtering section;

– use that does not comply with the information

expressly specified in this publication;

– serious shortcomings in the foreseen and recom-

mended maintenance operations;

– changes made to the filtering section or any unau-

thorised operation;

– using non-genuine spare parts or parts not speci-

fic to the model;

– total or partial failure to comply with the in-

structions;

– exceptional events.

Safety requirements

In the design and construction phases of the filter-

ing section have been adopted special measures to

avoid risks for the operators in the typical situations

of use during the technical life of the appliance and

especially in the following events:

•

installation

•

use

•

unit maintenance

Interventions on filtering section

Before any intervention on the unit please take the

following precautions :

•

cut off the power supply to the filtering section

•

please use suitable protective clothing.

•

don’t approach the unit with cravats, scarfs or

fluttering clothes, which could get trapped in the

filtering section.

•

assign the installation to qualified technical staff

•

please keep the working area clean

Please make sure that the earthing has been correct-

ly performed.

during maintenance, wait a few minutes after

switching off the filtering section and only work with

protective gloves.

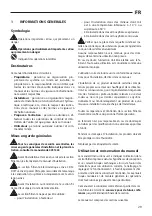

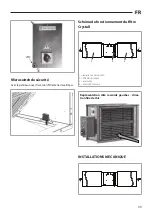

Unit identification

Each filtering section is supplied with an identifica-

tion plate giving details of the manufacturer and the

identification type.

POWER INPUT

CRYSTALL

TYPE

SIZE

CDS.C1 IAQ-50 QRS

../01

2022

230V 50Hz

QUALITY

CONTROL

PLENUM

FILTRANTE

SABIANA

S.p.A

Via Piave 53 - 20011 Corbetta (MI)

0044151

MADE

IN ITALY

16 W

General notes on delivery

The filtering section is supplied in cardboard

packaging.