24

*.*** mm

Display readout

Factory default setting

0.250 mm

Settings range

0 to 1.000 mm

(in increments of 0.025 mm)

Explanation

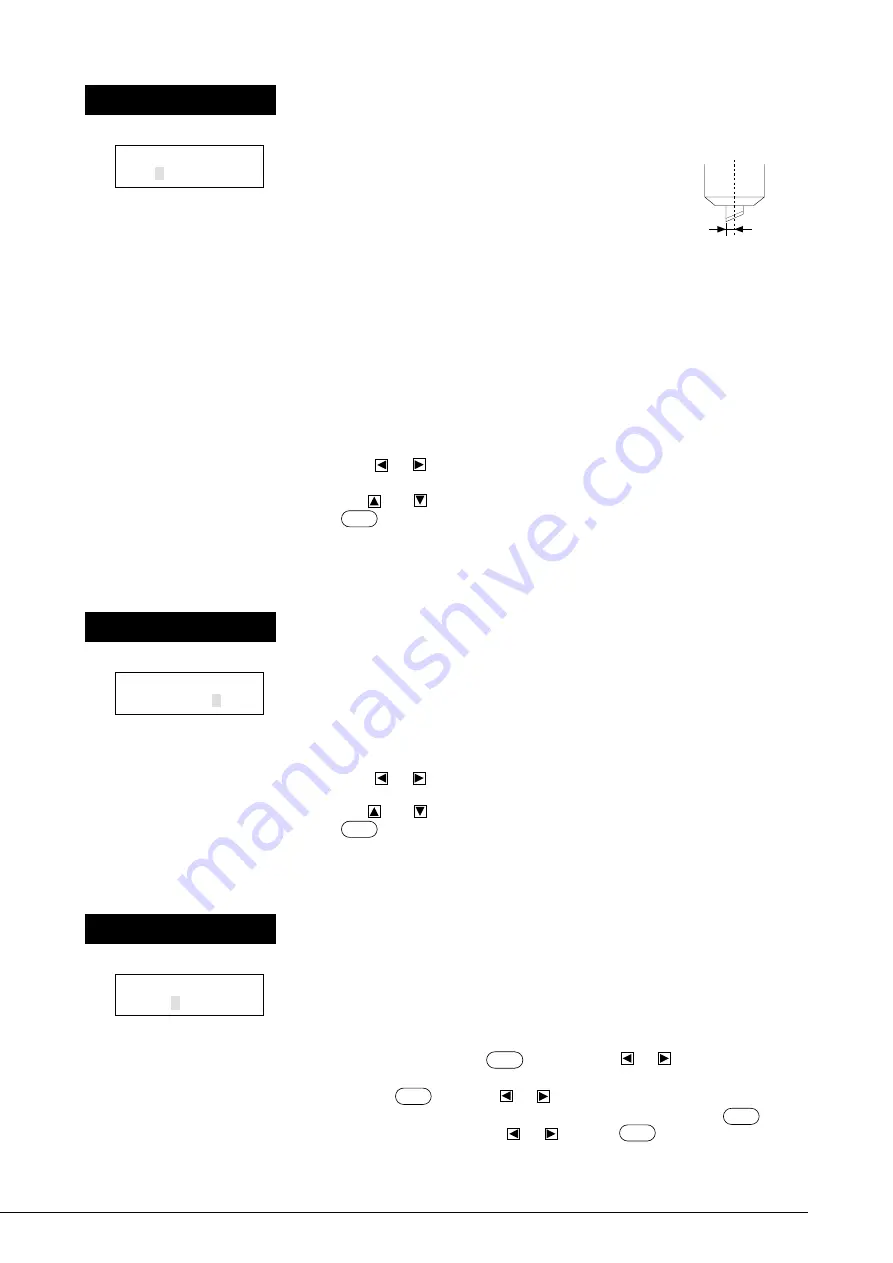

This sets the amount of offset from the center to the

cutting tip of the blade. When cutting two lines that form a

corner, this offset rounds the angle of intersection,

resulting in a rounded corner.

When blade compensation has been set, the PNC-1850/

1200 performs this compensation automatically.

The setting must match the conditions of the loaded sheet and blade. Perform a

cutting test and make the appropriate settings.

It is sufficient if the setting made here is within an adjustment range of

±

0.05 mm

from the offset value for the cutter blade. (For example, if the cutter blade is

0.250 mm, the setting should be between 0.200 and 0.300.)

The offset for the cutter blade included with the unit is 0.250 mm.

* When a pen has been installed to perform plotting, there is no need to set blade

compensation, because the tip of the pen lies along the center axis. In this case,

the setting “0.000 mm” should be made.

Procedure

This setting is made at the top menu.

Press

or

to move the blinking cursor to “ *.*** mm” on the left side of

the lower line of the display.

Use

and

to change the value. Display the value for the setting and press

ENTER

to save it.

For more details, refer to “1-4-5 Cutting Test” on page 15.

Setting blade compensation

1 CUT 50cm/s

0.250mm 30gf

Offset

Center axis

** gf

Display readout

Factory default setting

30 gf

Settings range

30—500 gf

(in increments of 10 gf)

Explanation

This sets the amount of pressure or force of the blade during cutting. The setting

must match the conditions of the loaded sheet and blade. Perform a cutting test

and make the appropriate settings.

Procedure

This setting is made at the top menu.

Press

or

to move the blinking cursor to “ *.*** mm” on the right side of

the lower line of the display.

Use

and

to change the value. Display the value for the setting and press

ENTER

to save it.

For more details, refer to “1-4-5 Cutting Test” on page 15.

Setting blade force

1 CUT 50cm/s

0.250mm 30gf

SMOOTHING

Display readout

Factory default setting

ON

Available settings

ON / OFF

Explanation

If you want the curves of circles and arcs to be cut smoothly, set this to “ON.”

When on, however, small text or intricate designs may also be cut with rounded

corners. If this happens, change the setting to “OFF” and perform cutting again.

Procedure

At the top menu, press the

MENU

key once. Press

or

to move the

blinking cursor to “SUBMENU” on the right side of the lower line of the display,

and press

ENTER

. Next, use

or

to move the blinking cursor to

“SMOOTH” on the left side of the lower line of the display, and press

ENTER

again. Change the value with

or

and press

ENTER

to save the new setting.

Cutting smooth curves

SMOOTHING

OFF <ON>