ADF MOTOR ASS’Y

SM 3-11

B173

Re

pla

ce

me

nt

and Adjus

tme

nt

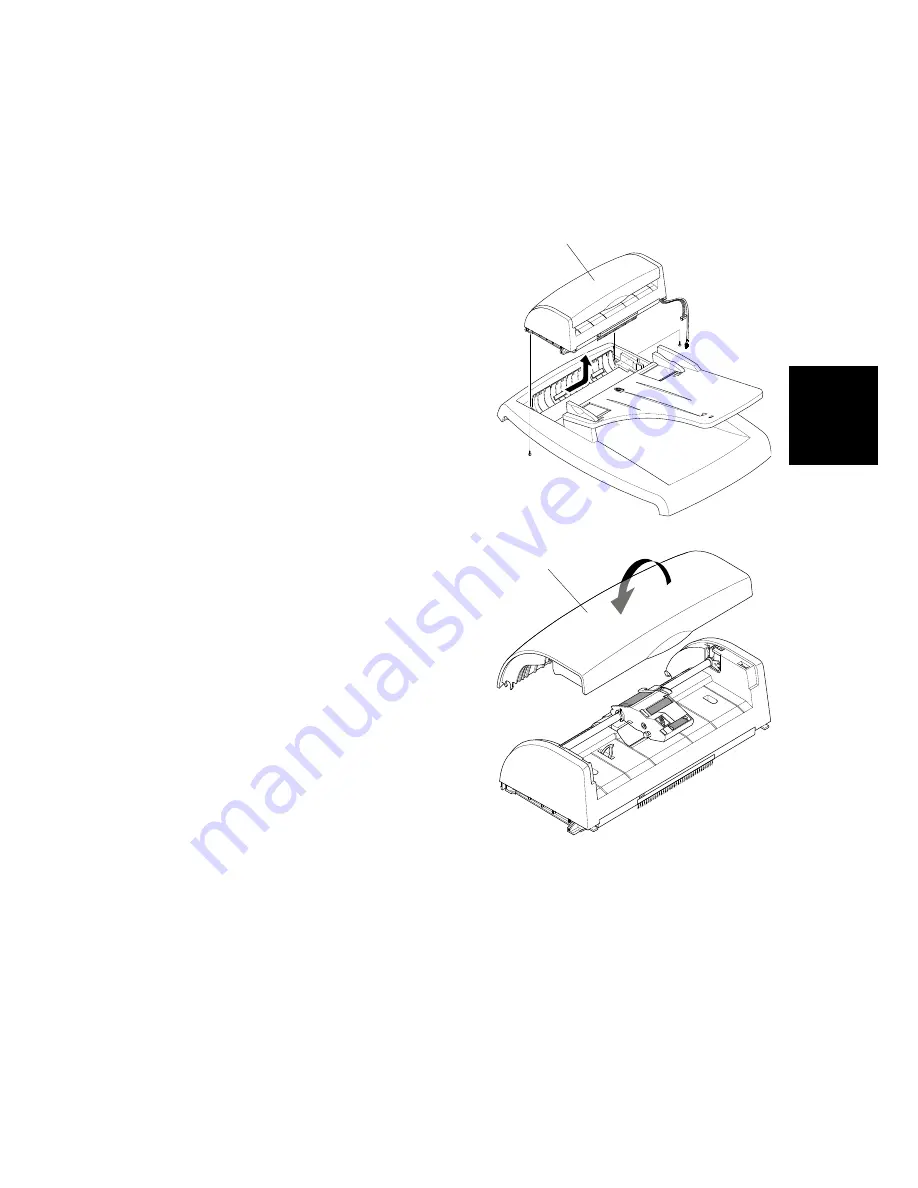

3.6 ADF MOTOR ASS’Y

1. Before you remove the ADF Motor Ass’y, you must remove these:

•

Rear Cover (

!

3.2)

•

Side Covers (

!

3.3)

•

Scanner Ass’y (

!

3.5)

2. Remove the two screws from the ADF

ass’y [A]. Then remove it.

3. Remove the open cover [B].

B173R923.WMF

B173R924.WMF

[A]

[B]

Summary of Contents for AC104

Page 1: ...B173 SERVICE DOCUMENTATION 001954MIU RICOH GROUP COMPANIES...

Page 2: ......

Page 3: ...B173 SERVICE DOCUMENTATION RICOH GROUP COMPANIES...

Page 4: ......

Page 5: ...B173 SERVICE DOCUMENTATION 001954MIU...

Page 6: ......

Page 8: ......

Page 10: ......

Page 12: ......

Page 24: ......

Page 26: ......

Page 27: ...INSTALLATION...

Page 28: ......

Page 30: ......

Page 31: ...PREVENTIVE MAINTENANCE...

Page 32: ......

Page 34: ......

Page 35: ...REPLACEMENT AND ADJUSTMENT...

Page 36: ......

Page 64: ......

Page 65: ...TROUBLESHOOTING...

Page 66: ......

Page 114: ......

Page 115: ...SERVICE TABLES...

Page 116: ......

Page 129: ...DETAILED DESCRIPTIONS...

Page 130: ......

Page 145: ...SPECIFICATIONS...

Page 146: ......

Page 154: ......

Page 155: ...APPENDIX...

Page 156: ......

Page 157: ...APPENDIX APPENDIX 1 B173 Appendix APPENDIX BLOCK DIAGRAM B173X900 WMF...

Page 158: ...APPENDIX B173 2 APPENDIX CONNECTION DIAGRAM B173X901 WMF...

Page 160: ......