20

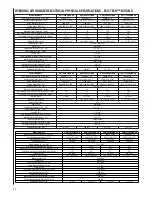

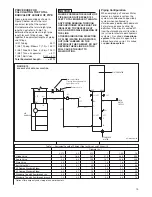

TABLE 1

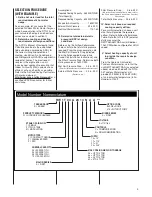

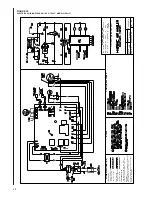

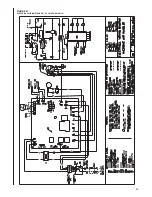

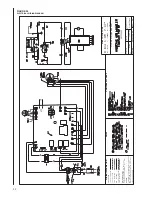

System Low Voltage Wiring

Diagrams

NOTE:

Local codes may require

thermostat wiring to be routed through

conduit or raceways. In such instances

splices can be made inside the Hydronic

Air Handler. All wiring must be nEC

Class I and must be separated from

incoming power leads.

Provide field-supplied disconnect for

maximum fuse or circuit breaker sizes, as

required by code.

Transformer is factory wired for 115V

operation.

The secondary circuit of the transformer

is protected by a 3-amp fuse mounted on

the printed circuit board.

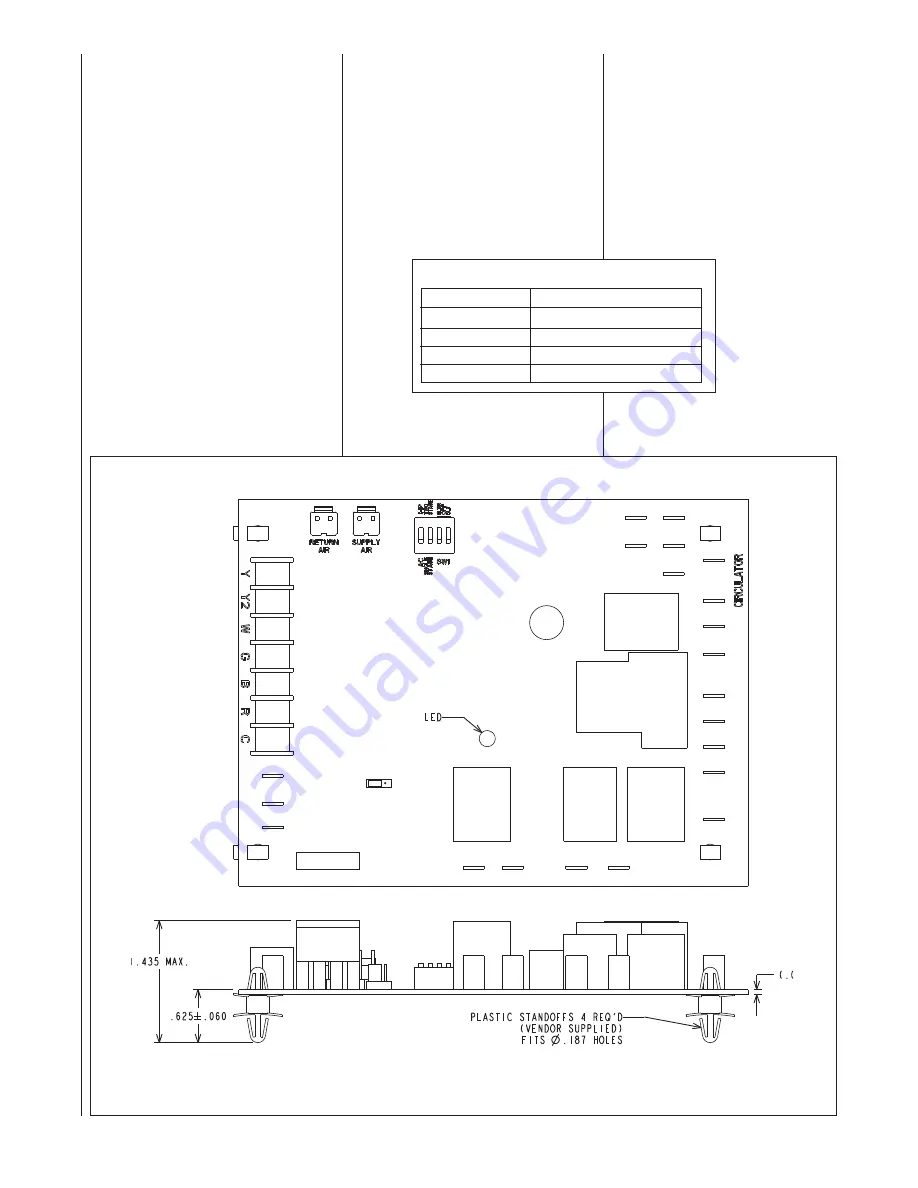

FIGURE 15

HYDRONIC AIR-HANDLER CONTROL BOARD (NON-MODULATING)

NOTES:

1. For proper operation of an open loop system (refer to Figures 11 and 17), the jumper (shunt) position on PCB point “P7” should be in

the FS position.

2. When changing shunt position ensure that unit power is turned off.

Wire Gauge Maximum Distance (feet)

18 gauge 60

16 gauge 100

14 gauge 160

12 gauge 250

Dip Switch Options:

Refer to the appropriate diagram for the

proper dip switch setting to be used with

the designed application (Figure 17).

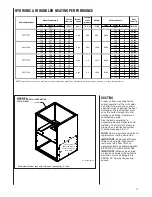

THERMOSTAT INSTALLATION:

Thermostat should be mounted:

• approximately 5 ft. (1.5 m) from floor

• close to or in a frequently used

room, preferably on an inside,

partitioning wall

• on a section of wall without pipes

or duct work.

Thermostat should nOT be mounted:

• close to a window, on an outside

wall, or next to a door leading to

the outside.

Summary of Contents for RW1P

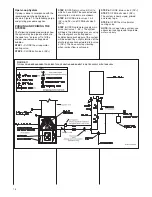

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...