6

Association, Inc., Batterymarch

Park, Quincy, MA 02269.” These

publications are:

• AnSI/nFPA no. 70-(Latest Edition)

national Electrical Code.

• nFPA90A Installation of Air

Conditioning and Ventilating

Systems.

• nFPA90B Installation of Warm Air

Heating and Air Conditioning

Systems.

• The equipment has been

evaluated in accordance with the

Code of Federal Regulations,

Chapter XX, Part 3280.

IMPORTANT INFORMATION

ABOUT EFFICIENCY AND

INDOOR AIR QUALITY

Central cooling and heating

equipment is only as efficient as the

duct system that carries the cooled or

heated air. To maintain efficiency,

comfort and good indoor air quality, it

is important to have the proper

balance between the air being

supplied to each room and the air

returning to the cooling and heating

equipment.

Proper balance and sealing of the

duct system improves the efficiency

of the heating and air conditioning

system and improves the indoor air

quality of the home by reducing the

amount of airborne pollutants that

enter homes from spaces where the

ductwork and/or equipment is

located. The manufacturer and the

U.S. Environmental Protection

Agency’s EnERGY STAR Program

recommend that central duct systems

be checked by a qualified contractor

for proper balance and sealing.

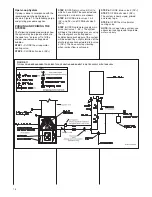

DUCT LEAkS CAN CREATE AN

UNBALANCED SYSTEM AND

DRAW POLLUTANTS SUCH AS

DIRT, DUST, FUMES AND ODORS

INTO THE HOME CAUSING

PROPERTY DAMAGE. FUMES

AND ODORS FROM TOXIC,

VOLATILE OR FLAMMABLE

CHEMICALS, AS WELL AS

AUTOMOBILE EXHAUST AND

CARBON MONOXIDE (CO), CAN

BE DRAWN INTO THE LIVING

SPACE THROUGH LEAkING

DUCTS AND UNBALANCED DUCT

SYSTEMS CAUSING PERSONAL

INJURY OR DEATH (SEE FIGURE

2).

• IF AIR-MOVING EqUIPMENT OR

DUCTWORk IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EqUIPMENT AND DUCT MUST

BE SEALED TO LIMIT THE

MIGRATION OF TOXIC FUMES

AND ODORS INCLUDING

CARBON MONOXIDE FROM

MIGRATING INTO THE LIVING

SPACE.

• IF AIR-MOVING EqUIPMENT OR

DUCTWORk IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH

AS WATER HEATERS OR

BOILERS - ALL JOINTS, SEAMS,

AND OPENINGS IN THE

EqUIPMENT AND DUCT MUST

ALSO BE SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE UL

CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDI-

TIONS AND ARE NOT COVERED BY

THE UNIT WARRANTY.

IN COMPLIANCE WITH

RECOGNIZED CODES, IT IS

RECOMMENDED THAT AN

AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS OR UNITS

CONTAINING EVAPORATOR COILS

OR AIR HANDLERS USED WITH

EVAPORATOR COILS THAT ARE

LOCATED IN ANY AREA OF A

STRUCTURE DAMAGE TO THE

BUILDING OR BUILDING CONTENTS

MAY OCCUR AS A RESULT OF AN

OVERFLOW OF THE COIL DRAIN

PAN OR A STOPPAGE IN THE

PRIMARY CONDENSATE DRAIN

PIPING.

required for the job specification.

• Read the entire instructions before

starting the installation.

• Some building codes require extra

cabinet insulation and gasketing

when unit is installed in attic

applications.

• If installed in an unconditioned

space, apply caulking around the

power wires, control wires,

refrigerant tubing and condensate

line where they enter the cabinet.

Seal the power wires on the inside

where they exit conduit opening.

Caulking is required to prevent air

leakage into and condensate from

forming inside the unit, control box,

and on electrical controls.

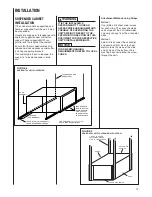

• Install the unit in such a way as to

allow necessary access to the

coil/pump and blower/control

compartment.

• Install the unit in a level position to

ensure proper condensate

drainage. Make sure unit is level in

both directions within 1/8”.

• Install the unit in accordance with

any local code which may apply

and the national codes. Latest

editions are available from:

“national Fire Protection

RECEIVING

Immediately upon receipt, all cartons

and contents should be inspected for

transit damage. Units with damaged

cartons should be opened

immediately. If damage is found, it

should be noted on the delivery

papers, and a damage claim filed

with the last carrier.

• After unit has been delivered to job

site, remove carton, taking care

not to damage unit.

• Check the unit rating plate for unit

size, voltage, phase, etc. to be

sure equipment matches what is

NOTICE

NOTICE

!

WARNING

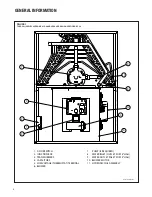

FIGURE 3

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

Summary of Contents for RW1P

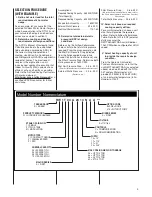

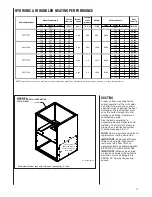

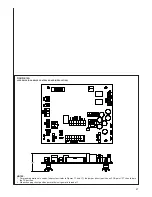

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

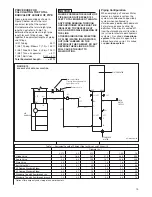

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

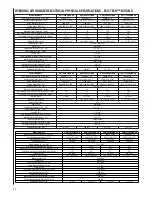

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...