16

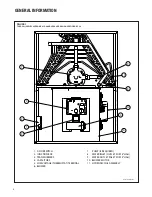

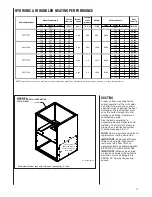

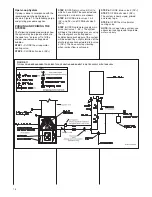

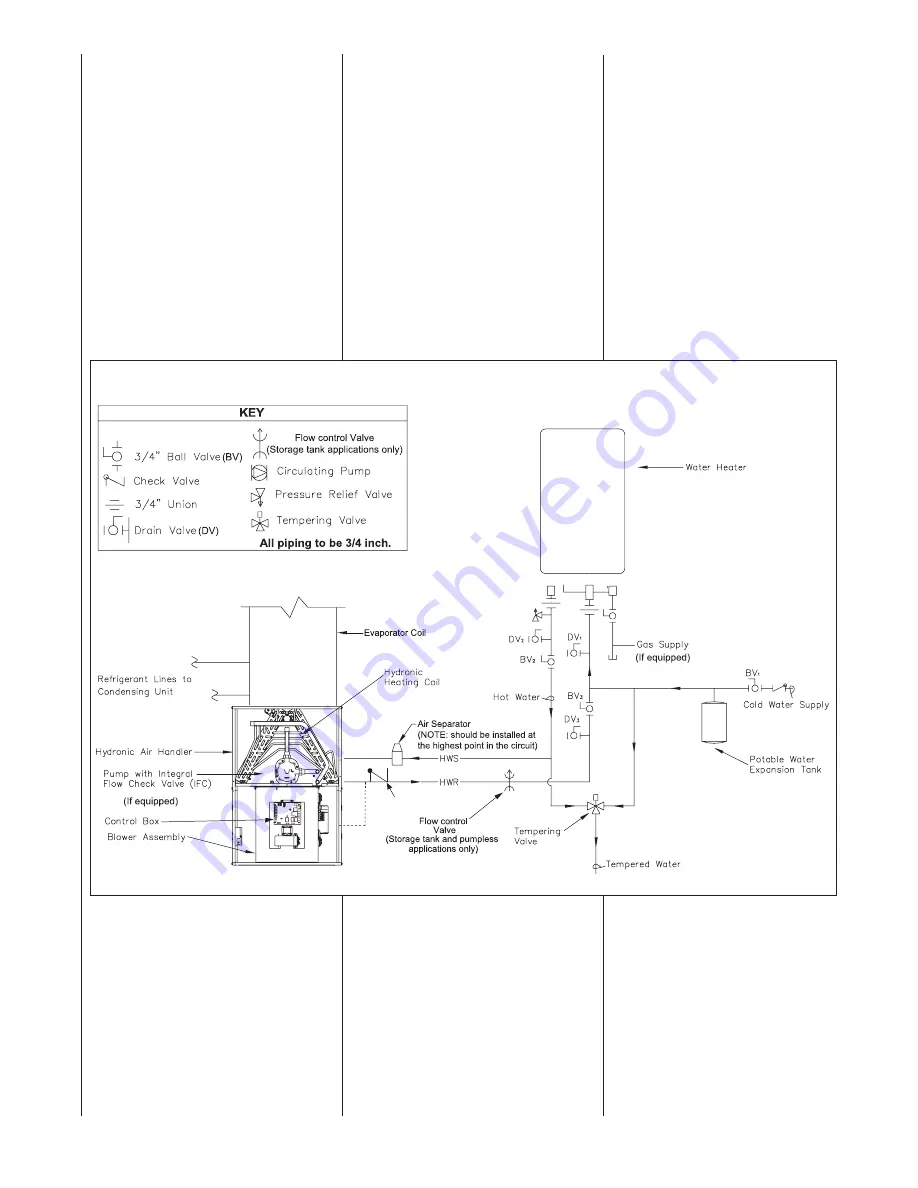

FIGURE 11

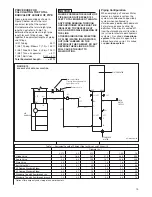

TYPICAL PIPING ARRANGEMENT FOR DIRECT SPACE HEATING AND DOMESTIC WATER SUPPLY WITH TANkLESS

Open-Loop System

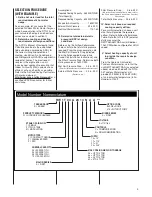

If piping is done in accordance with the

recommended schematic diagram

shown in Figure 10, the following purge

and priming procedure applies.

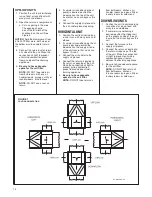

PURGING AND PRIMING THE

SYSTEM:

The following procedure describes how

the system may be piped to eliminate

the need for a “purge cart” to fill the

system and remove entrapped air

bubbles.

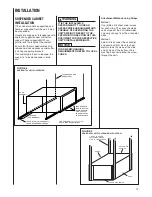

STEP 1:

CLOSE the air separator

venting valve.

STEP 2:

CLOSE ball valve 3 (BV

3

);

STEP 3:

OPEn drain valve 3 (DV

3

) to

which a hose MUST be connected and

draining to a sink, drain or outdoors.

STEP 4:

CLOSE drain valves 1 & 2

(DV

1

and DV

2

) and OPEn ball valve 2

(BV

2

).

STEP 5:

OPEn cold water supply main

valve (ball valve 1 - BV

1

). The system

will begin the prime/purge process using

the street pressure. Entrapped air

bubbles being pushed out of the system

will be evident by a slight vibration of the

discharge hose connected to drain valve

3 (DV

3

). The hose will stop vibrating

when laminar flow is achieved.

STEP 6:

CLOSE drain valve 3 (DV

3

);

STEP 7:

OPEn ball valve 3 (BV

3

).

The system is now purged, primed

and ready to go.

STEP 8:

OPEn the air separator

venting valve.

NOTE:

For an open-loop system, use

expansion tank approved for potable

water use only.

Pumpless only

ST-A1242-08-00

Summary of Contents for RW1P

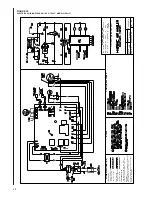

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

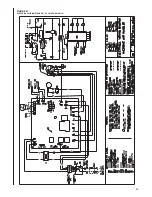

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...