23

blower tap (COOL_HI).

• When the thermostat ends the call for

cooling (Y), there is a 30 second

cooling off delay then the control de-

energizes the high blower tap

(COOL_HI).

• When the thermostat calls for

emergency heat (W), the hydronic

heating mode is activated.

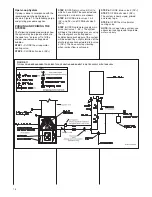

BLOWER TIME DELAY (HEATING

OR COOLING)

All models are equipped with a blower

time delay (BTD) in lieu of a blower relay

(BR) (see Figure 19). The blower will run

for 30 seconds after the blower time

delay (BTD) is de-energized.

DEFROST (DEFROST HEAT

CONTROL)

• For sequence of operation of defrost

controls, see outdoor heat pump

installation instructions.

• Supplemental heat during defrost can

be provided by connecting the purple

(PU) pigtail in the outdoor unit to the

W on the thermostat. This will

complete the circuit between R and W

through a set of contacts in the defrost

relay (DR) when the outdoor heat

pump is in defrost. This circuit, if

connected, will help prevent cold air

from being discharged from the indoor

unit during defrost.

• For most economical operation, if cold

air is not of concern during defrost, the

purple wire can be left disconnected.

Supplemental heat will then come on

only when called for by second stage

room thermostat.

EMERGENCY HEAT (HEATING

HEAT PUMP)

• If selector switch on thermostat is set

to the emergency heat positioin, the

heat pump will be locked out of the

heating circuit, and all heating will be

hydronic heat. Jumper should be

placed between W and E on the

thermostat sub-base so that the

electric heat control will transfer to the

first stage heat on the thermostat. This

will allow the indoor blower to cycle on

and off with the electric heat when the

fan switch is in the auto position.

SEQUENCE OF OPERATION

COOLING

Single Stage Cooling

• When the thermostat calls for cooling

(Y), there is a 1 second delay then

the control energizes the high blower

tap (COOL_HI).

• When the thermostat ends the call for

cooling (Y), there is a 30 second

cooling off delay then the control de-

energizes the high blower tap

(COOL_HI).

• A call for cooling has priority over

continuous fan.

HEATING (HYDRONIC)

• On a call for heating the pump will

start.

• After a sixty second delay the control

will look at the FS jumper if this is

jumpered the control will go into

water heating mode and ignore the

temperature sensors.

• If the air supply temperature is

greater than 85°F the control will

energize the indoor blower. If the air

temperature is less than 85°F the

control will turn off the pump and go

into a 5 minute delay.

• If the supply temperature is adequate

the main blower will then be

energized and run for 30 seconds.

• After the 30 second delay the control

will monitor the supply temperature. If

this drops the control will turn off the

pump and go into a 5 minute delay. If

the temperature is greater than the

shut off temperature the control shall

remain in heating mode.

• There must be a minimum delta of

10°F to remain in the heating mode.

• When the W call ends the pump shall

de-energize the blower shall turn off

after a blower off delay.

The FS input shall be used to allow a

way to bypass the system to allow it to

run. If this is jumpered the control will

ignore the temperature and go into a

heating cycle.

HEATING (Heat pump is the

primary source of heat)

Single Stage Heating

• The thermostat calls for heating (Y,

R, and B), there is a 1 second delay

then the control energizes the high

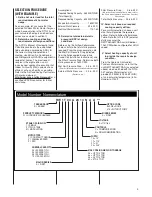

ROOM THERMOSTAT

(ANTICIPATOR SETTING)

See instructions with outdoor section,

condensing unit or heat pump for

recommended room thermostats.

• The thermostat should be mounted

4 to 5 feet above the floor on an

inside wall of the living room or a

hallway that has a good air

circulation from the other rooms

being controlled by the thermostat.

It is essential that there be free air

circulation at the location of the

same average temperature as other

rooms being controlled. Movement

of air should not be obstructed by

furniture, doors, draperies, etc. The

thermostat should not be mounted

where it will be affected by drafts,

hot or cold water pipes or air ducts

in walls, radiant heat from

fireplaces, lamps, the sun, T.V. or

an outside wall. See instructions

sheet packaged with thermostat for

mounting and installation

instructions.

MODULATING HEATING

(HYDRONIC)

On a call for heat, the pump will start.

After a two-minute delay the control

will start monitoring the supply air

temperature sensor.

If the air supply temperature is

greater than 85ºF the control will

energize the indoor blower. If the air

temperature is less than 85ºF the

control will go into a 5-minute delay.

The pump control will then begin to

control the system to try and maintain

a delta between the inlet water

temperature and the supply air

temperature. There is an adjustment

on the pump control 1 to 10. Each

point is a difference of 5 degrees. A

setting of 4 will provide a 20ºF

difference between the air and the

water temperatures.

Example: 120º Water inlet a setting of

4 will provide 100ºF leaving air

temperature.

If the supply air drops below 85ºF for

30 seconds the control will go into a

5-minute delay and restart the heating

cycle if necessary.

Summary of Contents for RW1P

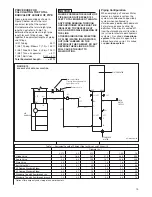

Page 29: ...29 FIGURE 21 ELECTRICAL WIRING DIAGRAM PSC MOTORS RW1P...

Page 32: ...32 FIGURE 24 ELECTRICAL WIRING DIAGRAM...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36 CM 0617...