18

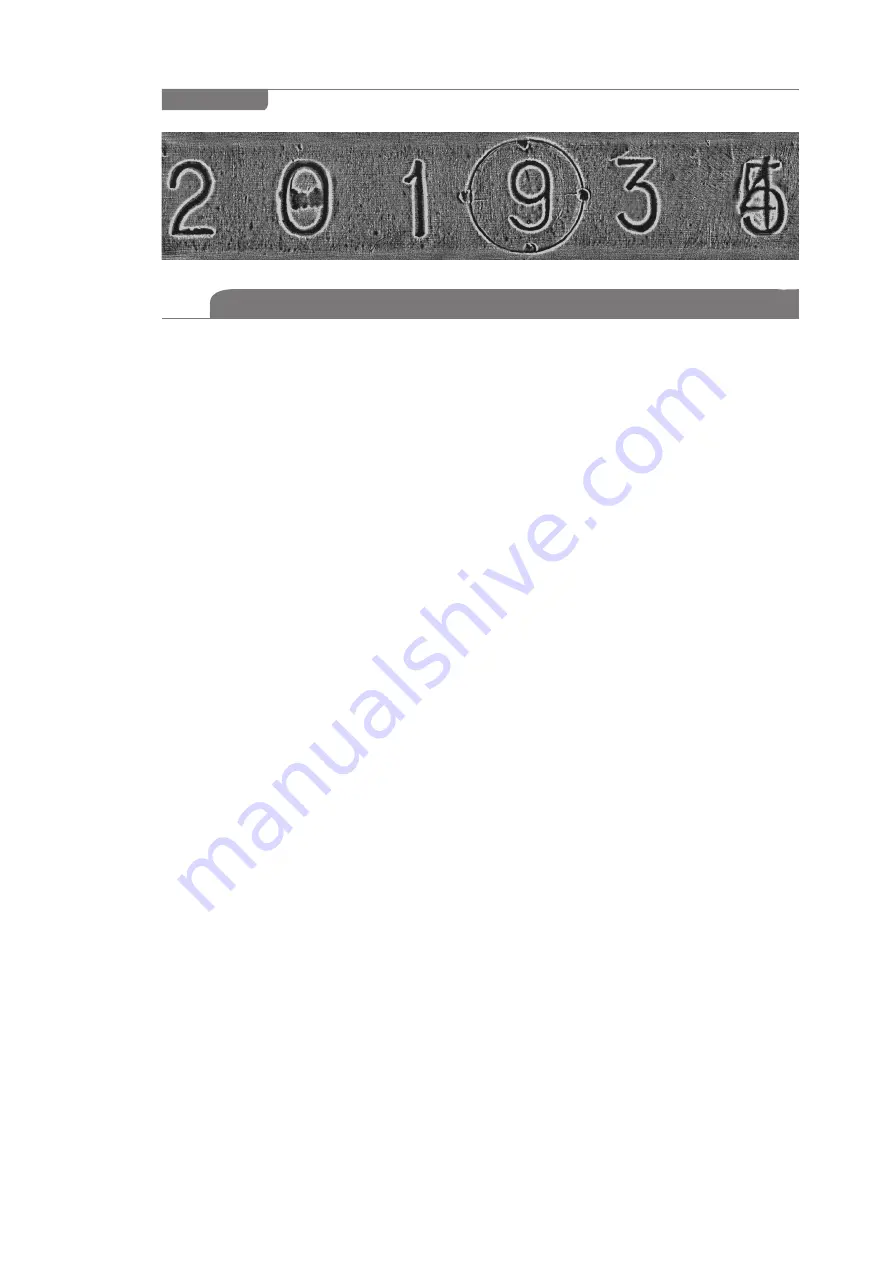

Magneto-optical visualization of the test object surface through the layer with thickness of 0,1 mm.

Spatial resolution is around 80 μm.

Figure 4

2.2.1.3 MOV USB device intended use

The MOV USB device performs the following operations:

z

magnetic copy stitching,

z

extracting a used magnetic copy,

z

processing and analyzing magnetic copy stitching,

z

documenting examination results.

Magnetic copy stitching:

z

Ensure that no magnetic tape is present in the OMB tape drive tract — neither the red

LED “MT in the buffer” (Figure 3, pos. 3), nor the green LED “MT in the tract” (Figure 3,

pos. 3) is on. Otherwise, first remove the previous magnetic copy.

z

For plastic MT. Put the MT with its working surface

(of brown colour) facing

down (facing the MOV USB device). It should be noted that when using ½’’ MT, it is

inserted into a paper cartridge beforehand. Then put the ½’’ MT with its working surface

(of brown colour) facing down while the paper cartridge is located on top of MT.

z

Straighten MT holding it by its edges and insert it into the tape drive (Figure 3, pos. 1).

Move MT into the tape drive to a depth of 30 mm (until blocked). The red LED (Figure 3,

pos. 3) lights up confirming the state “MT in the buffer” and the electric motor starts to

capture the tape. Move the tape further inside the tape drive tract until it is captured by

the drive shaft of the OMB. The green LED (Figure 3, pos. 3) lights up confirming the state

“MT in the tract”).

Release the MT strip and it will move forward automatically.

z

Wait for approximately 5 seconds to load the potentially informative sector of the magnetic

copy into MOV zone. Start the stitching process by corresponding software command.

The stitching process is confirmed by the green LED blinking (Figure 3, pos. 3) with

the meaning “MT in the tract”. The first visualization sub-frame appears on the PC screen.

z

Control the quality of stitching visually. When signs of low quality of magnetic copying

are observed (due to MT non-contact with the examined surface, MT or scanner warp

during copying, etc.), it is possible to stop the stitching process by clicking “Eject MT”.

As soon as MT is returned to the buffer, extract it, demagnetize, and make another

magnetic copy in conformity with paragraph 2.2.2.3.

z

If magnetic copy quality is satisfactory, stitching can be continued until the end of

the informative MT area and then stopped by clicking “Eject MT”, or you can wait until

OMB

stops in automatic mode (“MT end” LED comes on).

Extraction of the used magnetic copy

z

As soon as the command “Eject MT” is executed by the

OMB

, used MT automatically

returns to the buffer — to the tape drive or to the bunker (to the closest location).

The green LED “MT in the tract” fades and the red LED “MT in the buffer” comes on

indicating that MT stopped moving.

Do not remove an MT strip from the tape drive

until it stops completely and the LED “MT in the tract” is off!

z

Take MT by its edges and remove it from the buffer. The red LED “MT in the buffer” is to

go out. Then the used magnetic copy is to be demagnetized for reuse and placed into

the

CMS

case or it should be stored for further use.

Summary of Contents for 7517A

Page 2: ......