GB

Page 25 of 32

INSTRUCTION, USE AND

MAINTENANCE MANUAL

G1150.30MAGIC - G1150.30MAGICIT

RAVAGLIOLI S.p.A.

7107-M001-0_R

Fig. 51

Fig. 50

• Periodically, with a frequency of at least once a month,

lubricate the arms of the bead breaking roller and of

the tools.

13.0 ROUTINE MAINTENANCE

To guarantee the efficiency and correct functioning of the

machine, it is essential to carry out daily or weekly clean-

ing and weekly routine maintenance, as described be-

low.

Cleaning and routine maintenance must be conducted

by authorized personnel and according to the instruc-

tions given below.

• Disconnect the mains power supply before starting

any cleaning or routine maintenance operations.

• Remove deposits of tyre powder and other waste ma-

terials with a vacuum cleaner.

DO NOT BLOW IT WITH COMPRESSED AIR

.

• Do not use solvents to clean the pressure regulator.

• The conditioning unit is equipped with an automatic

vacuum-operated drain therefore it requires no manual

intervention by the operator (see

Fig. 50

).

IN ORDER TO ALLOW A LONGER

LIFE OF THE FILTER AND OF ALL

MOVING PNEUMATIC DEVICES,

YOU HAVE TO MAKE SURE THAT

THE SUPPLIED AIR IS:

• EXEMPT FROM THE LUBRICATING

OIL OF THE COMPRESSOR;

• EXEMPT FROM HUMIDITY;

• EXEMPT FROM IMPURITY.

THE MANUFACTURER DOES NOT

ACCEPT ANY DAMAGE RESULTING

FROM THE FRAILURE TO OBSERVE

THE ABOVE INSTRUCTION, AND

SUCH FAILURE COULD INVALIDATE

THE WARRANTY!!

BEFORE CARRYING OUT ANY MAIN-

TENANCE OPERATIONS, MAKE

SURE THERE ARE NO WHEELS

CLAMPED ON THE CHUCKING TA-

BLE AND THAT ALL SUPPLIES TO

THE MACHINE HAVE BEEN DIS-

CONNECTED.

13.1 Lubricants

Special lubricant for spindle movement control gearbox.

Use

ESSO GEAR OIL GX140

.

Lubricate slides, screws/nut screws or racks and pin-

ion with a soft brush using lubricant of

ESSO GP

type.

ANY DAMAGE TO THE MACHINE

DEVICES RESULTING FROM THE

USE OF LUBRICANTS OTHER THAN

THOSE RECOMMENDED IN THIS

MANUAL WILL RELEASE THE

MANUFACTURER FROM ANY LI-

ABILITY.

• Immediately replace worn parts, bead breaking roller,

assembly tools.

• Every

week

and/or when necessary, top up the oil tank

using the filler hole provided closed by a cap or screw

on the lubricator filter.

N.B: This operation should not be carried out by

unscrewing the cup of the lubricator filter.

• The use of synthetic oil might damage the pressure

regulator filter.

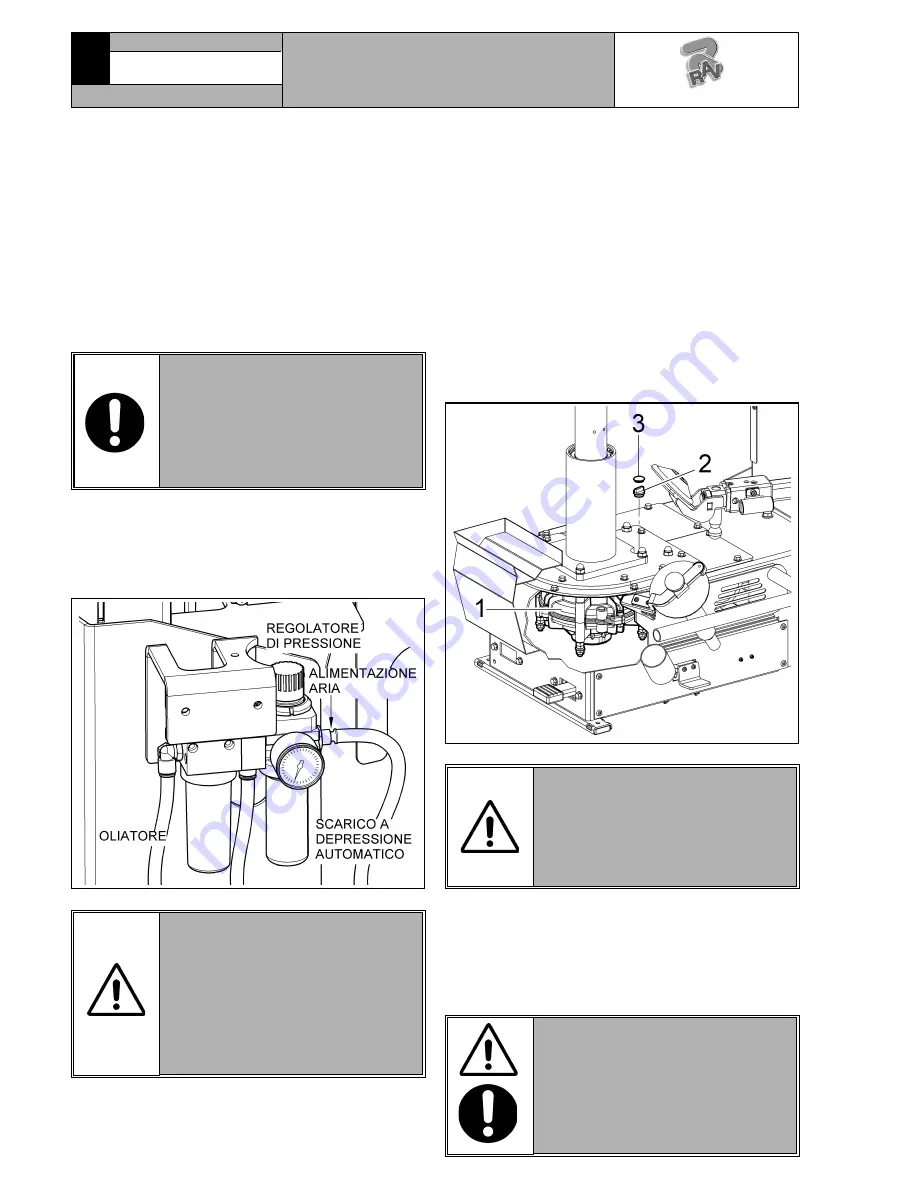

• At regular intervals, (at least every 100 working hours)

check reduction gear (

Fig. 51 pos. 1

) lubricating oil

level. Such operation must be effectuated removing the

plug (

Fig. 51 pos. 3

), positioned on the provided hole

prearranged on the frame, and removing the plug po-

sitioned on reduction gear (

Fig. 51 pos. 2

).