- 68 -

Procedure for activation of checkweighing mode

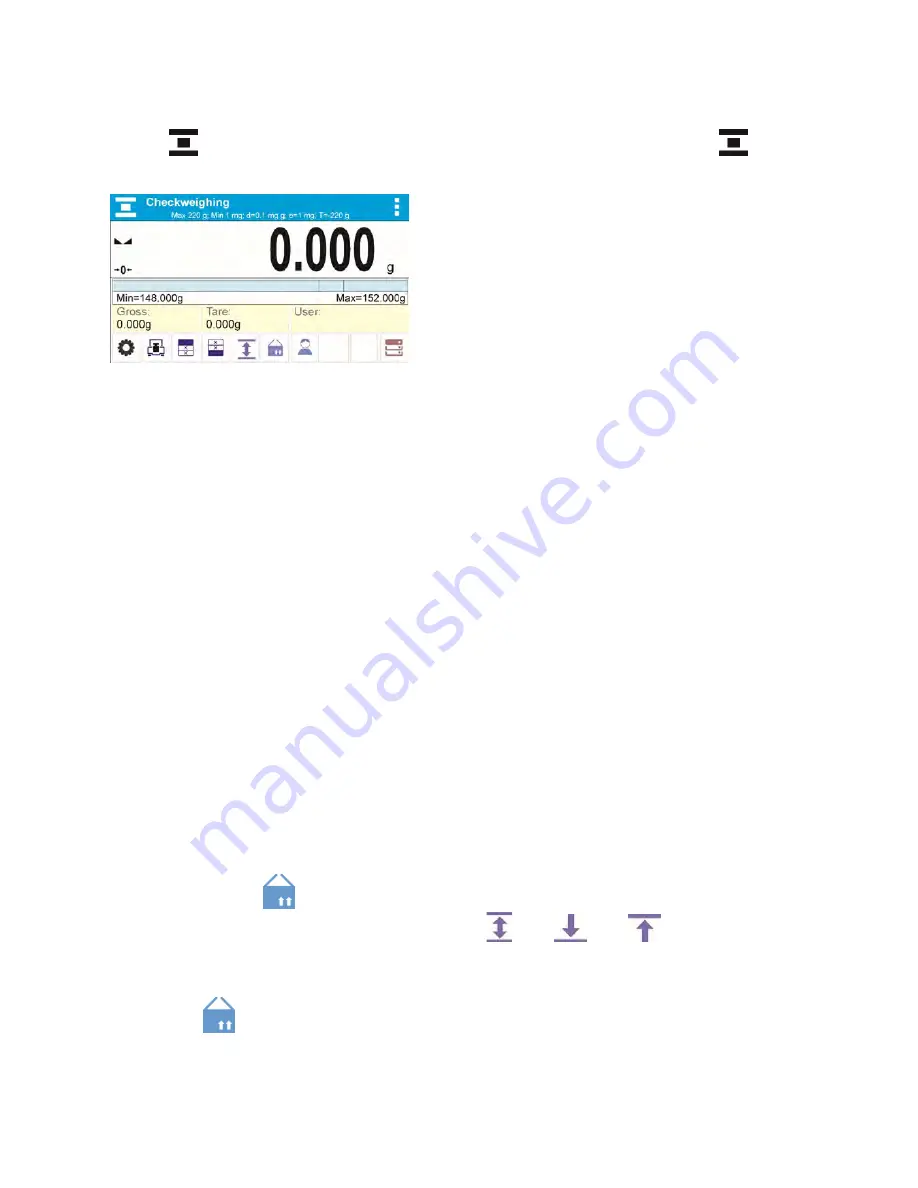

Select <

Checkweighing> mode, home screen featuring checkweighing pictogram

in a top

bar is automatically displayed.

Info field provides the following information:

•

Bar graph with checkweighing thresholds

•

Gross weight,

•

Tare weight,

•

User,

•

Keys: parameters, adjustment, print header, print footer, specify checkweighing thresholds,

product, user, databases.

14.1. SUPPLEMENTARY SETTINGS FOR CHECKWEIGHING MODE

The supplementary settings enable adjusting the working mode to your needs and requirements.

For means of operation of these functions read point 8.10 „WEIGHING mode settings”.

You can place the bar graph within information field area. Below the bar graph, Min and Max

threshold values are displayed.

14.2. CHECKWEIGHING – QUICK ACCESS KEYS

Each working mode features automatically displayed set of default keys. The set can be modified by

assigning out-of-list quick access keys to on-screen keys. Such operation requires particular

permissions level.

Read section 7.6.1 for list of quick access keys.

14.3. MAKING USE OF CHECKWEIGHOING THRESHOLDS

In order to use checkweighing thresholds:

•

Select product <

> with Min and Max threshold declared

•

Enter numerical value for the thresholds using <

> or <

> or <

> button, in this case

thresholds do not refer to any product.

PROCEDURE 1

– selecting product from Products Database

•

Press <

Products Database> key.

•

Using product list, select the product that is to be weighed.

•

The balance displays threshold values under the bar graph within INFO area. Bar graph colour

corresponds to the current status of weight:

Yellow colour: weight value below Min threshold value

Summary of Contents for AS X2 Series

Page 7: ...7 1 GENERAL INFORMATION 1 1 DIMENSIONS AS X2 series PS X2 series...

Page 8: ...8 APP X2 series WLC X2 series...

Page 96: ...96 Status Completed Signature...

Page 132: ...132...