LCC/LGA Module Series

Module Secondary SMT User Guide

Module_Secondary_SMT_User_Guide 18 / 25

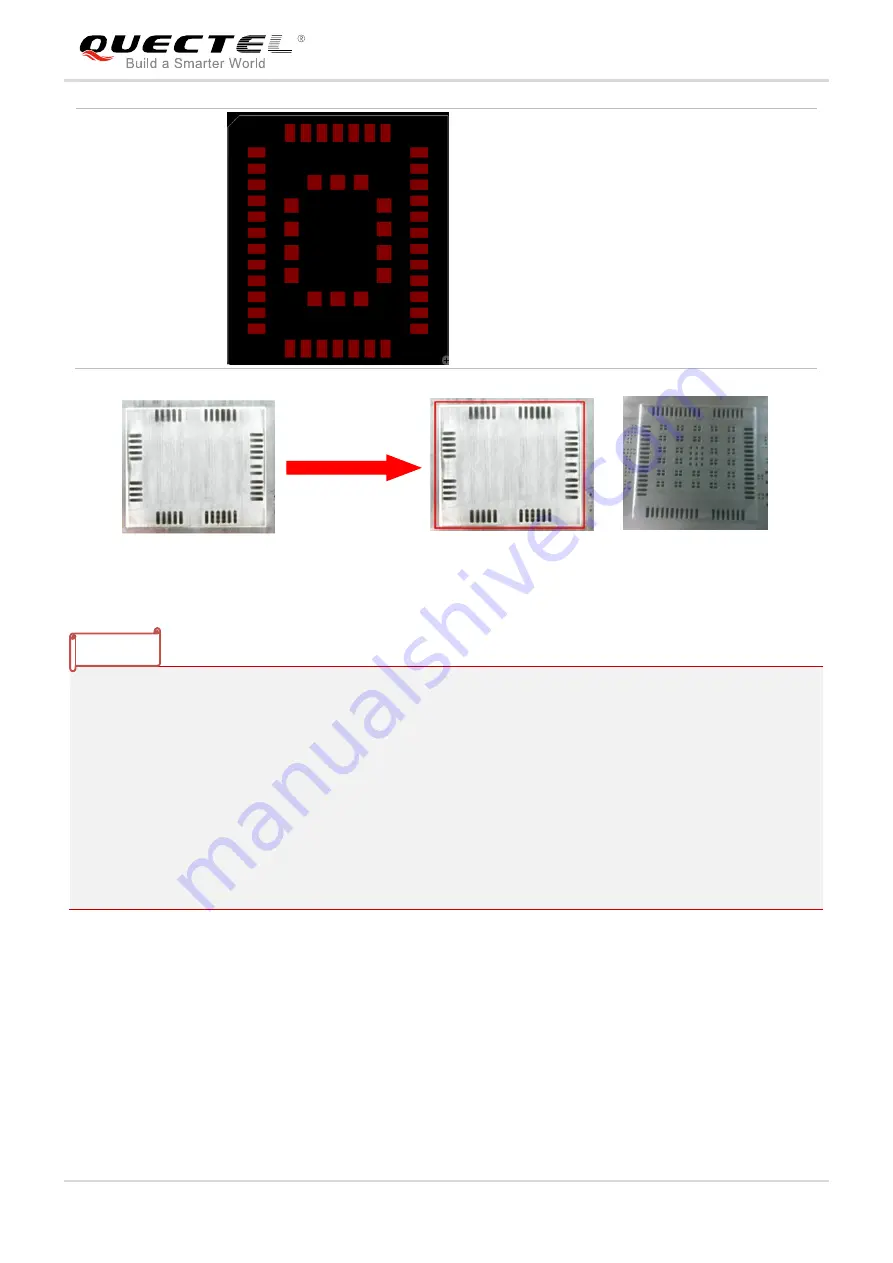

AF20

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.13-0.15mm.

2. For pads on four sides:

The stencil aperture for each pad should

be centered with area reduced to

75%-85% and the shape should be

rectangle with round chamfers.

3. For square pads in the center:

The stencil aperture should be designed

into round with area reduced to 70%.

Figure 3: Step-up Stencil Area

1.

“*” means under development.

2. Area of the stencil apertures for components within 1mm from the thickened stencil part should be

reduced by 10%-30% compared with regular apertures, since the thickening will increase the volume

of solder paste. For components with 0.5mm pitch (or smaller) or 0201 components, please keep at

least 3mm space in between, otherwise there may be a risk of solder bridging that will cause short

circuit of the component.

3. You can optimize the stencil design depending on the actual situation.

4. Inward shrinking and outward extending are relative to the host PCB footprint of the module. For

details of the recommended footprint, please refer to the hardware designs of corresponding

modules.

4.3. Mounting Process

4.3.1. Load Materials

In order to ensure mounting accuracy, for single modules that have been unpacked for baking, it is

recommended for the customers to use a dedicated tray/fixture for module loading.

NOTES