LCC/LGA Module Series

Module Secondary SMT User Guide

Module_Secondary_SMT_User_Guide 17 / 25

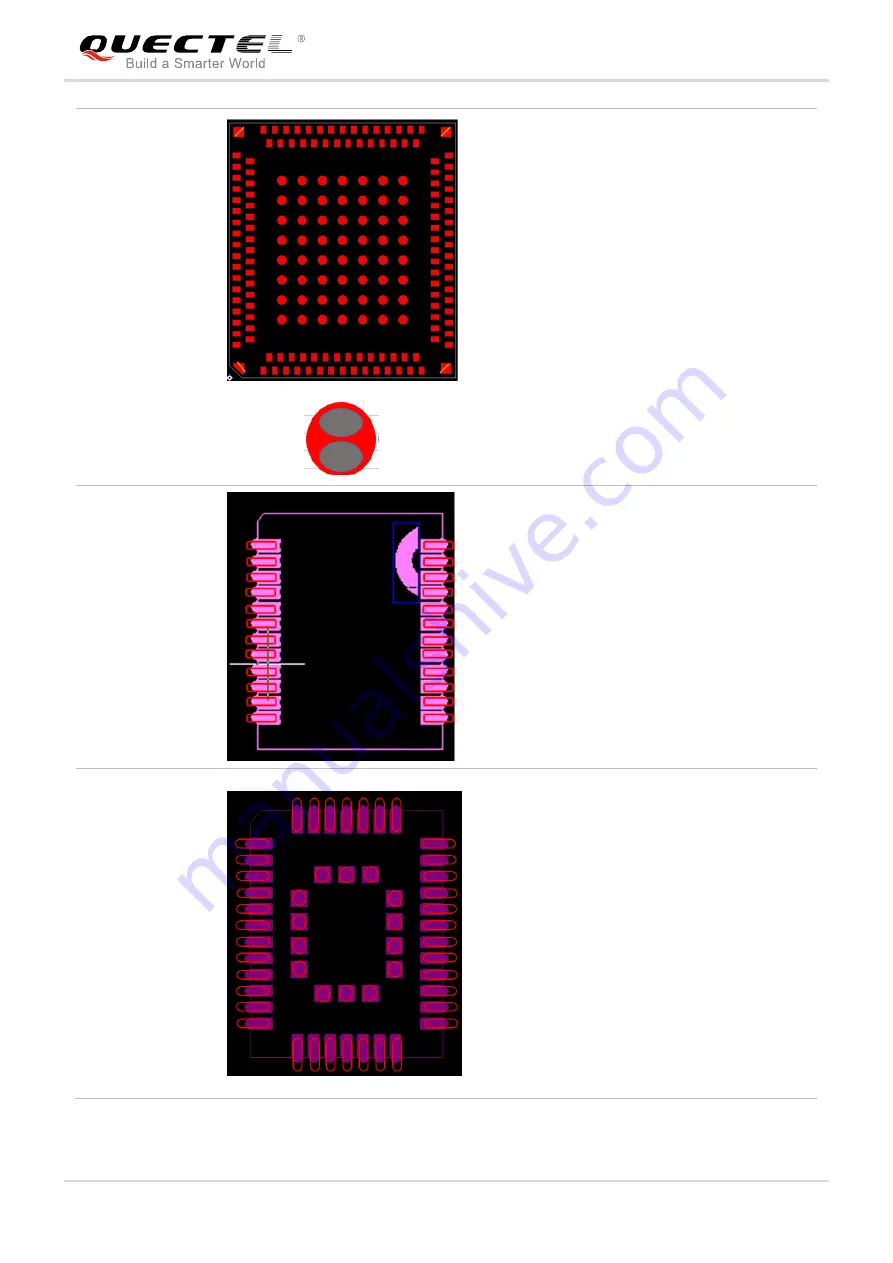

AG15

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.13-0.15mm.

2. The stencil aperture area for the pads on

four sides should be centered with area

reduced to 75%-85%, and should be

designed with round chamfers.

3. For pads at four corners, the aperture should

be centered and designed into diagonal-

patterned lines with 60% area of the

corresponding pad.

4. The aperture for round GND pads in the

center should be designed into 2 ovals with

60%-70% area of the pad, as shown by the

2 grey parts in the figure at the bottom.

FC10

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.15-0.18mm.

2. The innermost edge of the aperture for each

single pad should be shifted outward by

0.20mm and the outermost edge should be

shifted outward by 0.40mm, and the width

should be reduced in a ratio of 1:0.85, and

should be designed with round chamfers.

3. There is no need to design stencil apertures

for the arc-shaped pad in blue box.

FC20

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.15-0.18mm.

2. For pads on four sides:

The innermost edge of the aperture for each

single pad should be shifted outward by

0.20mm and the outermost edge should be

shifted outward by 0.40-0.60mm while the

width should be reduced in a ratio of 1:0.85,

and should be designed in rectangle with

round chamfers.

3. For pads in the center:

The stencil aperture should be designed into

round with area reduced to 70%.