LCC/LGA Module Series

Module Secondary SMT User Guide

Module_Secondary_SMT_User_Guide 12 / 25

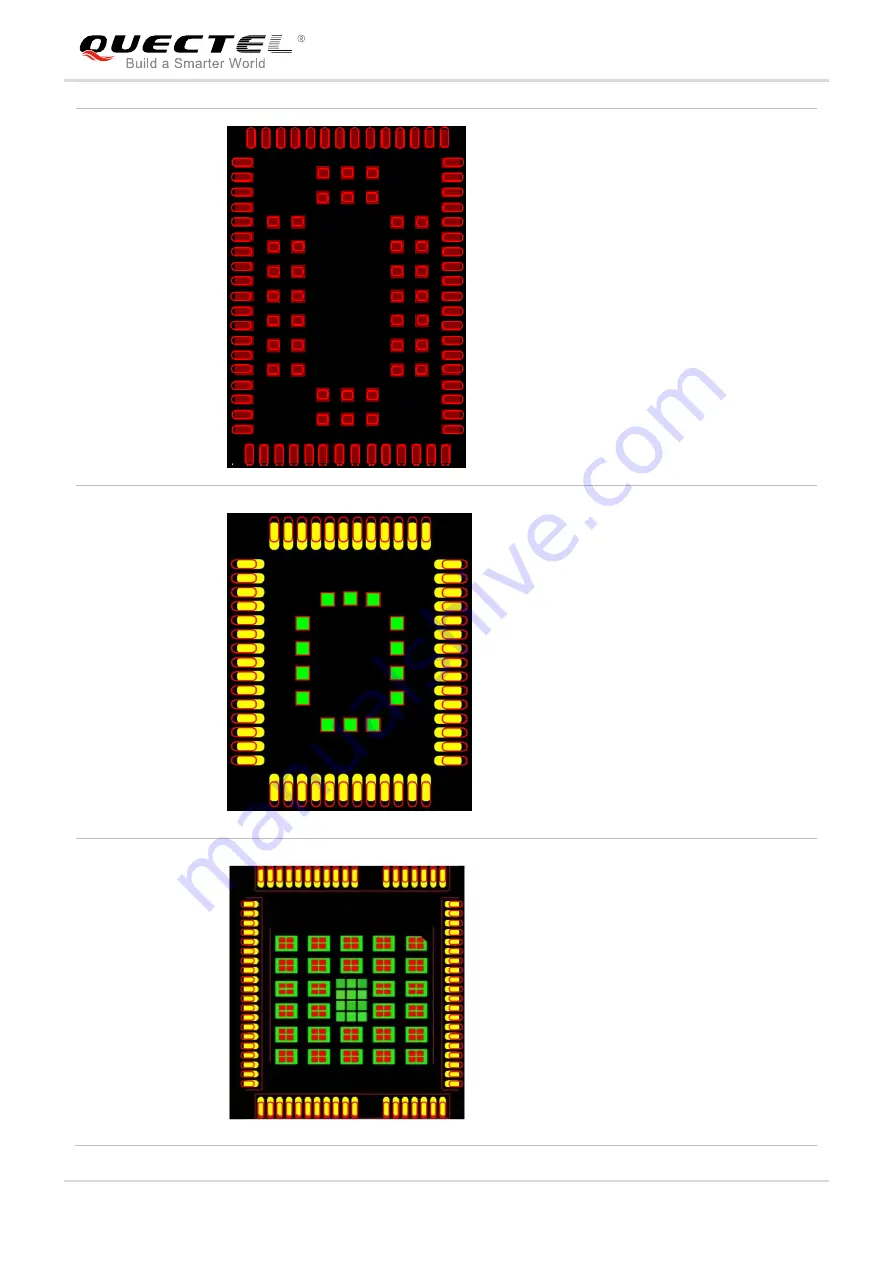

M89

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.18-0.20mm.

2. For pads on four sides:

The innermost edge of the aperture for each

single pad should be shifted outward by

0.20mm and outermost edge should be

shifted outward by 0.40-0.60mm, and the

width should be reduced in a ratio of 1:0.85.

And the shape should be rectangle with

rectangle with round chamfer.

3. For pads in the center:

The stencil aperture for each single pad

should be centered with area reduced to

70%, and should be designed with round

chamfers.

MC60

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.18-0.20mm.

2. For pads on four sides:

The innermost edge of the aperture for each

single pad should be shifted outward by

0.20mm and outermost edge should be

shifted outward by 0.40-0.60mm, while the

width should be reduced in a ratio of 1:0.85.

And the shape should be rectangle with

round chamfers.

3. For pads in the center:

The stencil aperture for each pad should be

centered with area reduced to 70%. The

shape should be square.

UC20/UC15

1. The stencil thickness of the area for the

module should be partly stepped-up to

0.18-0.20mm.

2. For pads on four sides:

The innermost edge of the aperture for each

single pad should be shifted outward by

0.20mm and the outermost edge should be

shifted outward by 0.40-0.60mm. The width

should be reduced in a ratio of 1:0.85. And

the shape should be rectangle with round

chamfers.

3. For GND pads in the center:

Design the stencil aperture for each pad into