6

1

2

3

4

5

6

7

8

For more information access our catalog, in the section of security and

accessories.

http://www.automatismospujol.es/arxiusdb/cataleg/cataleg.pdf

English

MOUNTING OPERATIONS

REGULATION OF THE OPENING LIMIT-SWITCH (Fig. 16)

Drill in the shutter's central shaft (Fig. 4) one hole Ø 10 mm. in order the operator doesn't turn, and

Fix the door to the pulley with the supplied pulley fixing ring, fan-type lock washer and M10x25

another Ø 12 mm. for the electric wire. If possible, place the operator in the centre of the shutter's

countersunk bolt. If the pulley of the door and the pulley of the motor are not the same size, apply

shaft in an easy position for opening the micro-switches lid to make the wire and the regulation of

the 220 mm adaptor. Move manually the opening stop collar (B) up to the regulation of the opening

the limit switches. In case of electric brake, make another drill of Ø 10 mm. for the cable of the

of the door. [Fig.12). Check the travel and adjust it if necessary.

manual release.

REPLACEMENT OF THE ELECTRIC WIRE

For a correct replacement of the electric wire respect the following indications:

Open the pulley unscrewing the M8x25 screws remove the plastic roller band without folding it and

Cut out the electric connection.Take out the lid that covers the micro switch removing the 2 screws.

keep it in a clean place. Separate the gear-motor's body removing the 4 screws with the 6mm. (fig.

Unscrew the 3 wires and the ground. Remove the stuffing box and take out the cable (if does not

5). hexagonal wrench.

slide cut it).Loosen all the wire fixings to the electronic board.

Couple the two parts of the gear-motor around the door's shaft and joint them screwing the 4

Unwire the cable from the board.

Substitute the wire for another cable with standard (4x1HO5 VVF) in case of bi-motor (4x1.5 HO5

screws on the gear-motor's support (fig. 6)

VVF).

Tighten the M10x40 screw (Fig. 8 A) entering it into the Ø 10 mm. hole of the shutter's shaft.

Wire the new cable doing the same operations in the inverse sense.

Put again the plastic roller band in its place.

Switch on the motor and check its correct direction. If not, change the black wire and the brown

Apply again the pulley by coupling the two parts and tighten the screws.

one. Make reference to the connection board indicated in the assembling instructions paying

Screw also the M10x40 (Fig. 8 B), bi-motor (fig. 10 B). Pressing on the shaft till the gear-motor is

attention to the position of the common motor (N).

blocked and tighten the nut.

GUARANTEE

The operator should be fixed, lined and the pulley must turn freely.

The Company guarantees all products against any production fault for a period of 2 years following

Make a hole Ø 12 mm. in the last canvas of the shutter at the same location of the hole and nut M10

the supply date.

of the pulley (Fig. 11). If the shutter is waved or not regular, it is necessary to couple a flat metal piece

LIABILITIES

of 1 meter to the pulley.

The Company is obliged to undertake repairs of the equipments under guarantee, following

Travel the electric cable trough the shaft's hole de Ø 12 mm. (Fig. 14), avoiding any contact with the

revision by the technical department.

rotating parts and make the wires. In case of motor with electric brake travel also the brake cable

All the equipments that, due to emergency, are delivered before the decision they are actually

through the hole of Ø 12 mm. drilled in the shaft, and mount the manual release.

For a proper release the flexible cable of the brake should not do any exaggerated curve.

under guarantee, will be considered as a standard order to be paid. Faulty equipment replaced

under guarantee will remain of property of the Company. The replacement of such equipments will

ELECTRIC WIRE (Fig. 14)

be on the installer's account and charge.

It is very important to respect the connection of the common of the motor (N) and the earth

connection. The model with electro brake comes already wired. If the automatism is not

CANCELLATION

provided with electro brake, bridge the contacts (A, B fig 14). With electro brake, remove the

The equipment will not be under guarantee in the following cases:

bridge and on the same terminals connect the reel. SECURITY STANDARD: The connection wires

should come from a differential switch.

-

incorrect choice of the equipment given the door's characteristics

CHECKING THE OPERATION DIRECTION (Fig. 16)

-

the mounting and connecting instructions have not been followed

Place the closing stop collar (C) until the click of the opening micro-switch is heard (fig. 16) Give

-

payment has not been settled

power, if the motor stops at closing it's correct. If not, cut the power and change the position of the

phase wires, or the two wires that go to the control unit, or activate it manually by means of the push

button or the key switch. Continue respecting the common jumper of the motor (N).

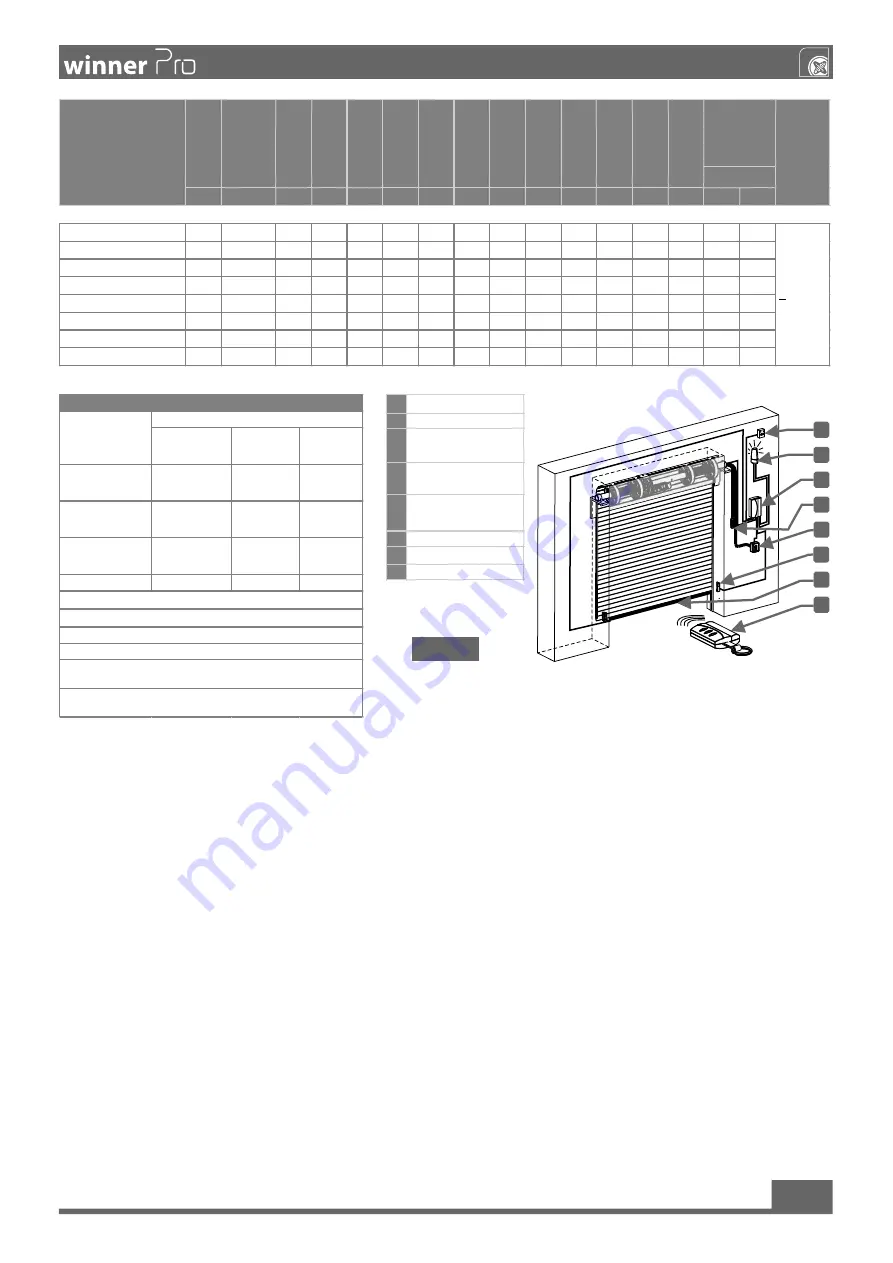

1

Bipolar switch

2

Flashlight

3

Electronic board with

built-in receiver

4

Manual unlocking of the

actuator

5

Key switch 2 and

external brake release.

6

Photocells

7

Security band

8

transmitter

Expert people

(outside a public

area *)

Expert people

(public area)

Unlimited use

In the presence of

someone

A

B

X

With pulses in sight

(eg sensor)

C o E

C o E

CyD,oE

With impulse not in

sight (on remote

control)

C o E

CyD,oE

CyD,oE

Automatic

CyD,oE

CyD,oE

CyD,oE

D

: Sensors to detect obstacles and / or other devices that limit forces

betw een limits of standards EN 12453 - Appendix A.

E

: Photocells placed as indicated in EN 12445 point 7.3.2.2 for the w hole

height of the door up to a maximum of 2.5 m).

USE OF THE CLOSURE

TYPE OF CONTROL

* A typical example is the closures that do not access the public w ay.

A

: Pulsating command w ith dead man ( w ith sustained action),

B

: Key selector w ith dead man.

C

: Regulation pow er motor.

Com ponents to be installed according to EN12453

Kg.

V

HZ

W

A

Nm

Kg.

ºC

ºC

uF

206

220

WPRO V17 400/200 EF

7

220-240V 50/60 400

2,15

105

100

20

10

20

-20

+50

14

7,7

8,4

8,9

WPRO V17 400/200

6

220-240V 50/60 400

2,15

110

105

20

10

20

-20

+50

14

7,7

8,4

8,9

WPRO V17 600/200 EF

7,8

220-240V 50/60 600

2,7

168

160

20

10

20

-20

+50

18

7,7

8,4

8,9

WPRO V17 600/200

6,8

220-240V 50/60 600

2,7

178

170

20

10

20

-20

+50

18

7,7

8,4

8,9

WPRO V17 630/200 EF

8,3

220-240V 50/60 630

2,8

189

180

20

10

20

-20

+50

20

7,7

8,4

8,9

WPRO V17 630/200

7,3

220-240V 50/60 630

2,8

199

190

20

10

20

-20

+50

20

7,7

8,4

8,9

WPRO V17 1260/200 EF

12,9 220-240V 50/60 1260

5,6

357

340

20

10

20

-20

+50

20

7,7

8,4

8,9

WPRO V17 1260/200

11,9 220-240V 50/60 1260

5,6

367

350

20

10

20

-20

+50

20

7,7

8,4

8,9

T.

M

IN

.

TYPE

O

PE

RA

TO

R

W

EI

G

H

T

PO

W

ER

SU

PP

LY

FR

EQ

U

EN

C

Y

PO

W

ER

C

U

RR

EN

T

TO

RQ

U

E

M

A

X,

LI

FT

IN

G

M

A

X,

CY

CL

ES

PE

R

D

A

Y

RP

M

IP

<70dB(A)

T.

M

A

X.

CA

PA

CI

TO

R

LI

M

IT

SW

IT

CH

M

A

X.

PU

LE

Y

TU

RN

S

MAX. HEIGHT

BLIND 10 mm.

N

O

IS

IN

ES

S

PULEY

Fig.20