AVH-P3100DVD/XN/UC

98

1

2

3

4

1

2

3

4

C

D

F

A

B

E

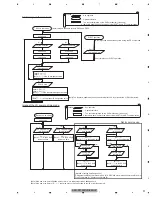

Connector (relay FFC)

Relay FFC

Fig. 1

Fig. 2

GND the brown line

4V to the gray line

Mecha Module_Bringing into the Clamp State with No Disc Loaded

1. Remove the relay FFC from the connector on the module PCB side (Fig. 1).

(Precaution) When it is difficult to apply 4V to the motor in procedure 2 below, remove the connector on the relay

PCB side, then remove the FFC, and remove the solder of the CRG motor lead and apply voltage to the lead.

2. Push the Disc detection arm while applying 4V to the CRG motor (Fig. 2)

By this action, the mecha moves to the clamp state and the PU moves to the outer periphery.

3. Stop the motor when the PU comes to the vicinity of the intermediate periphery.

(Precaution) If the PU goes to the outer most periphery, it idles.

It is not a problem, but please try not to let it idle as much as possible.

Summary of Contents for AVH-P3150DVD

Page 29: ...AVH P3100DVD XN UC 29 5 6 7 8 5 6 7 8 C D F A B E ...

Page 61: ...AVH P3100DVD XN UC 61 5 6 7 8 5 6 7 8 C D F A B E Side A SCLOCK SDATA D CP_ RESET D DGND2 ...

Page 67: ...AVH P3100DVD XN UC 67 5 6 7 8 5 6 7 8 C D F A B E ...

Page 114: ...AVH P3100DVD XN UC 114 1 2 3 4 1 2 3 4 C D F A B E 9 1 PACKING ...

Page 116: ...AVH P3100DVD XN UC 116 1 2 3 4 1 2 3 4 C D F A B E 9 2 EXTERIOR 1 A A A B ...

Page 118: ...AVH P3100DVD XN UC 118 1 2 3 4 1 2 3 4 C D F A B E 9 3 EXTERIOR 2 A A E F 2 1 ...

Page 123: ...AVH P3100DVD XN UC 123 5 6 7 8 5 6 7 8 C D F A B E ...

Page 127: ...AVH P3100DVD XN UC 127 5 6 7 8 5 6 7 8 C D F A B E ...

Page 145: ...AVH P3100DVD XN UC 145 5 6 7 8 5 6 7 8 C D F A B E ...