3

3. Calibration of light source for Digital adjustment

Execute Calibration of light source before Digital adjustment.

When replace the light source or master lens for 76180 (D20 or D20-01), this calibration is

necessary.

[Required equipment]

K10D

Master body for calibration

(PENTAX Corporation will rend the master body. Please contact with us)

Adjusting software for 76830

Computer (Windows 2000 or Xp, support USB)

Light source (Example: LV3300, A light source)

Master lens for 76180 (D20 or D20-01)

*Use the same master lens as the ID number printed on

CD- ROM to adjust it accurately.

3-1. Setting for computer

Complete the [2. Setting for computer and prepare the SD card] of [PREPARTAION].

(Use Digital adjustment software)

3-2. Calibration of light source

(1) Before calibration, turn ON the light source and leave 30 minutes for stabilizing light source.

(2) Calibrate Color temperature and Brightness by using color meter and LV checker as shown below table.

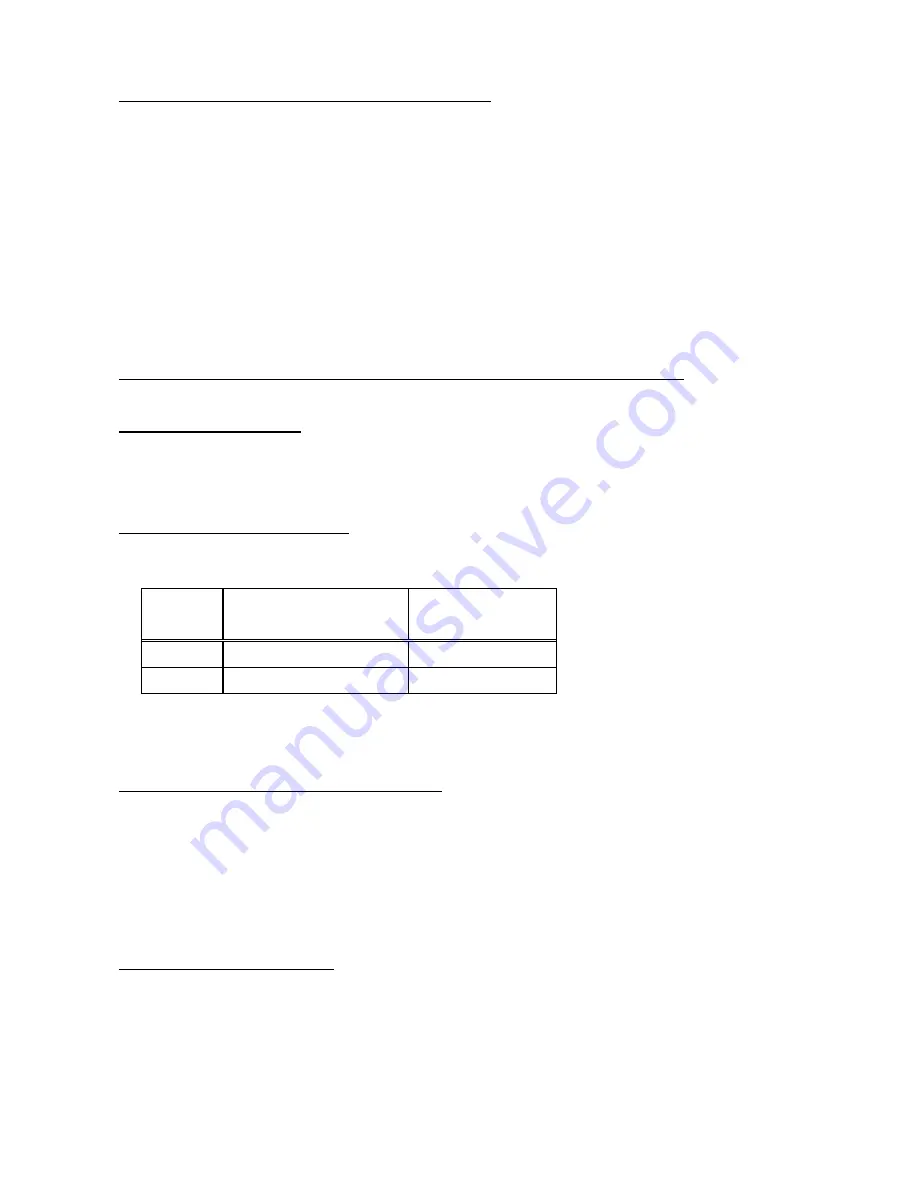

Light

source

Brightness

Color

temperature

LV12

LV12.00Ev ±0.50

2,856K ±30

LV11 LV11.00Ev

±0.01

-

*Calibrate with using the master body according to the following procedure.

3-3. Setting for Master body and Master lens

(1) Set the mode dial to [M].

(2) Set the focus mode lever to [MF].

(3) Set the SR lever to [OFF]

(4) Attach the master lens and F8 set ring to the body.

(5) Set the aperture to [F8 position].

3-4. Procedure for calibration

(1) Connect the AC adaptor to the master body.

(2) Connect to PC with USB cable.

(3) Turn ON the power and confirm that the camera is recognized by PC.

(4) Set the light source to [LV12].