Parker EME

Setting up Compax3

192-120100 N16 C3I10T10 - December 2010

135

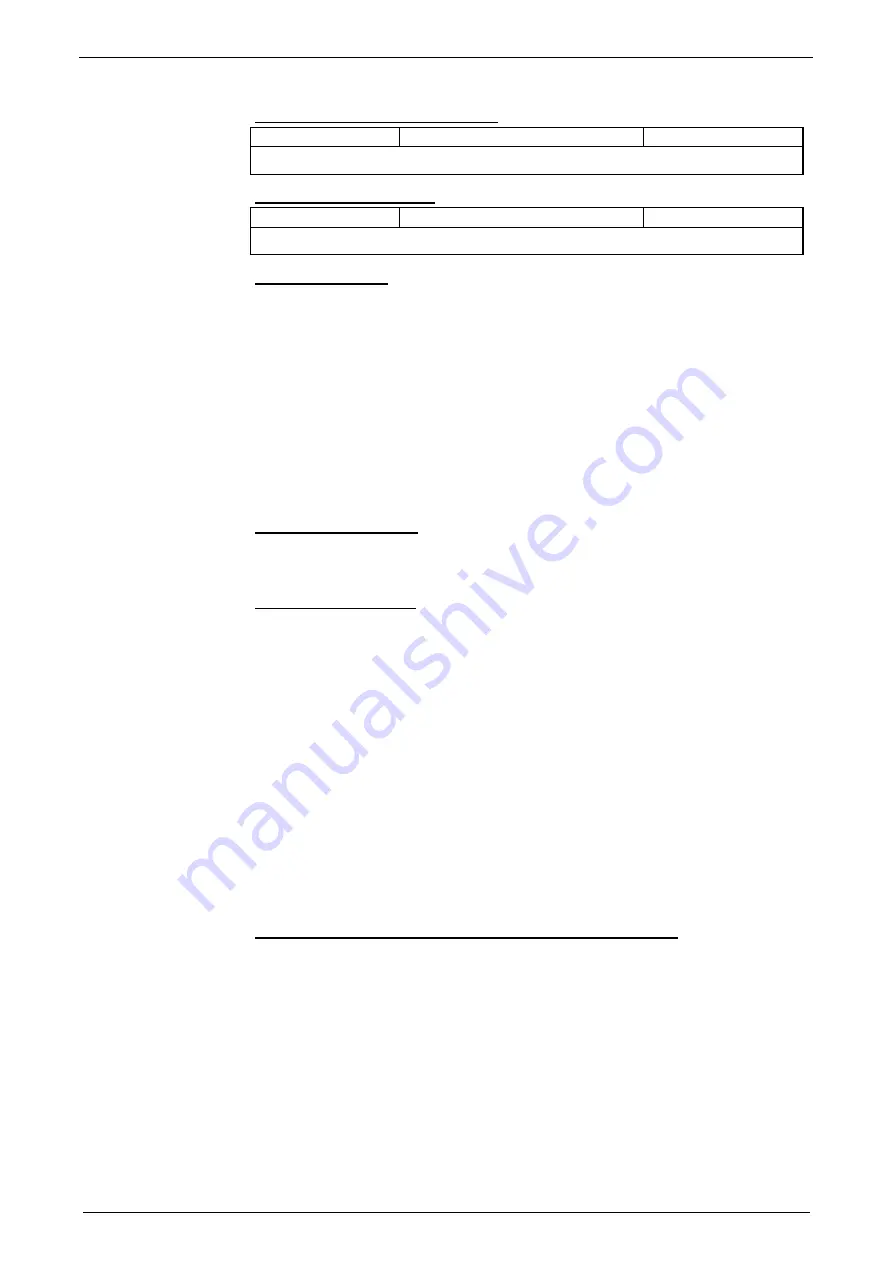

Unit: %

2100.6: Filter - Actual acceleration

Range: 0 ... 550

Standard value: 100

Uni

t: %

2100.4: Moment of Inertia

Range: 10 ... 500

Standard value: 100%

For motors with distinct transition from static friction to kinetic friction in connection

with a noisy feedback signal, where a control oscillation is generated at standstill, 3

optimization objects are available:

Position controller

Deadband (Object 2200.20)

Following error filter (object 2200.11) and

Friction compensation (Object 2200.21)

The control oscillation at standstill is eliminated by the deadband.

Please note, however, that the possible exactitude is reduced by the deadband.

The use of the following error filter and the friction compensation can reduce the

deadband.

A noisy feedback signal necessitates to set an unnecessarily large deadband.

Noisy feedback signal:

To avoid this, the time constant of the following error filter can be increased.

The following error can be reduced faster with the aid of friction compensation,

which will reduce the deadband.

Friction compensation

The objects (deadband, following error filter, friction compensation) are stored in

the motor library. Therefore these objects are overwritten when configuring another

motor.

PowerRod

When configuring a PowerRod, the deadband (+/-25µm) and the following error are

preassigned, the friction compensation is switched off.

Remaining motors of the motor library

For all other motors (not PowerRod), the objects are preassigned with "0".

Forward control measures

Forward control of rotation speed, acceleration and current

Minimal following error

Improves the transient response

Gives greater dynamic range with lower maximum current

Application:

Note:

Advantages: