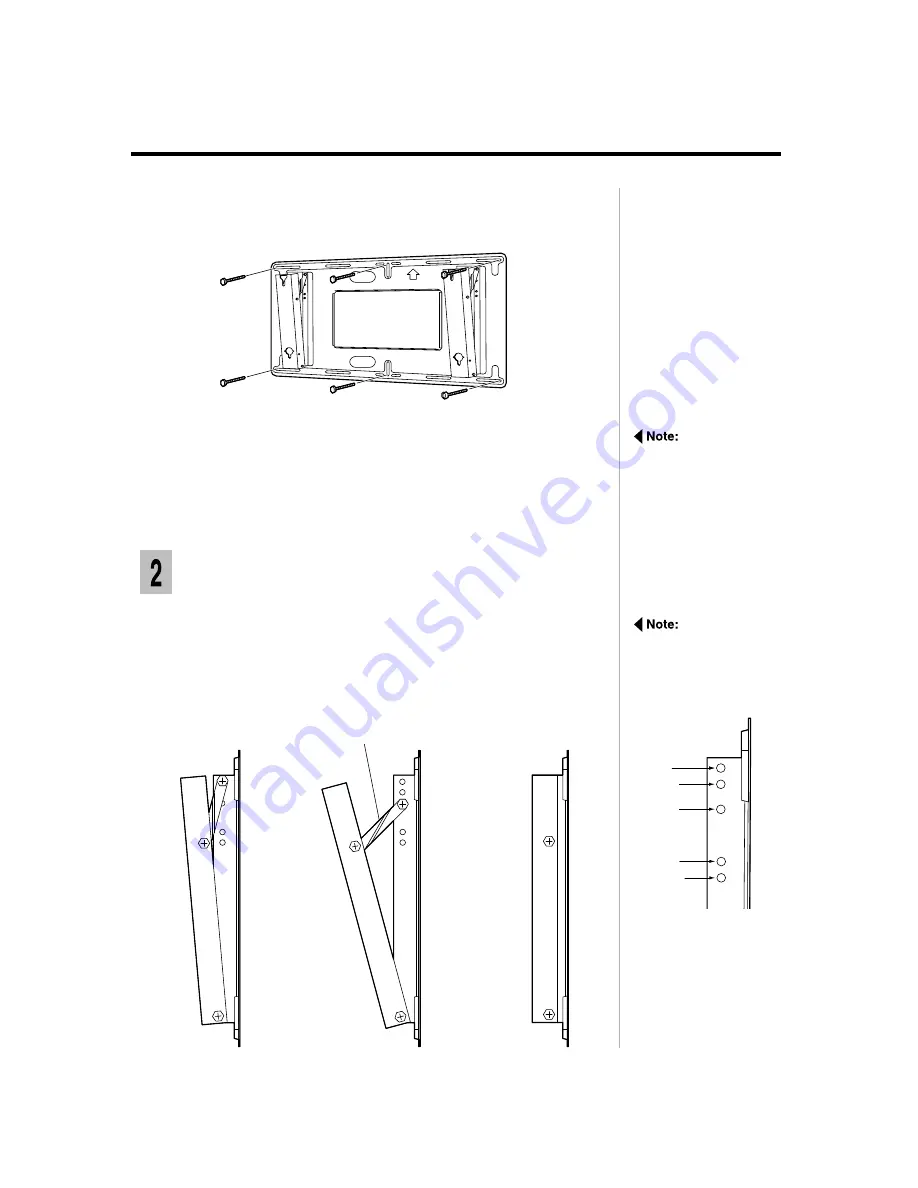

Adjusting the angle of the display fitting

If the screws protrude

more than 5 mm, it will

not be possible to install

the Wide Plasma Display

in the correct position.

Use a level gauge to correct the alignment of the wall-hanging bracket,

and screw bolts into the remaining five holes.

3

5-

4

The stay is not needed if

the display unit is to be

fixed vertically.

Angle adjustment positions

The angle of the display fitting can be adjusted to one of the five positions

ranging from vertical to 20 tilt in 5 steps.

At the time of shipment, the angle of tilt is set to 5 from vertical. To change

this angle, adjust the position of the stay.

5tilt

10tilt

15tilt

20tilt

No tilt

5

10

15

20

0

stay

5 tilt

15 tilt

No tilt

Provisionally tighten the fixing screws.

After determining the positions and checking them against the bracket,

embed M6 bolts or nuts. Furthermore, when embedding the bolts, ensure

that the bolts protrude from the wall by 10 to 15 mm.

4

Summary of Contents for TY-SP42PM3W

Page 10: ......

Page 31: ...4 3 Installation diagram For Multi Screen Units mm 90 120 Installe lower panel unit first ...

Page 45: ...Description Installation diagram Units mm in 626 926 Ceiling board 5 0 4 3 1 660 89 6 2 ...

Page 59: ...Matsushita Electric Industrial Co Ltd Central P O Box 288 Osaka 530 8692 Japan ...