60

10.2. Troubleshooting-2 (when an error message is displayed on PC)

Error Code

Possible Cause

Check Point

Classified Code ST1

ST2

ST3

ST4

Hold the document before opening the ADF Door when a paper jam error occurred, to get the stop position of the document.

U11: Document

did not reach to

the Starting Sen-

sor position.

(Document

remains

between the

Starting Sensor

and Paper

Sensor.)

or Double Feed

occurred around

the paper feed

section.

11

00

00

00

1. Rollers (Paper Feed,

Double Feed Prevention) are

dirty.

1. Clean the rollers with Roller Cleaning Paper.

2. Perform the

"Feed"

test to check paper feed

mechanism.

3. Perform the

"Cleaning Mode"

for cleaning roller

with Service Utility.

2. Paper Feed Roller or

Double Feed Prevention

Roller is not installed

properly.

(

2. Perform the

"Feed"

test in Sec.

).

3. Rollers have reached their

life expectancy.

1. Replace the Paper Feed and Double Feed

Prevention Rollers after checking each roller

configuration and scanner counter of Service

Utility.

2. Perform the

"Feed"

test in Sec.

).

3. Perform the

"Clear Counter"

for replacing roller

with the Service Utility.

4. ADF Door is not closed

tightly.

After opening the door, close it slowly until it clicks

into place.

5. Paper dust exists on or

around the Starting Sensor.

1. Clean up the dirt with cleaning paper or cotton

swab or soft and dry cloth.(See Sec.

2. Execute

"Key / Sensor"

and

"Sensor Sensitive

Level"

test in Sec.

) to check the sen-

sor condition.

6. Starting Sensor does not

work correctly.

1. Execute

"Key / Sensor"

test in Sec.

(

check the sensor condition.

2. Check the sensor alignment is proper (whether the

sensor direction faces to its light guide.)

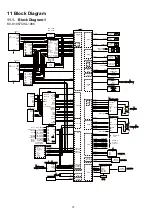

3. Check the following connection and soldering con-

dition on each connector.

CN2301 ( STARTING SENSOR Board) to CN9

(CONTROL Board)

4. Check the following signals

a. STARTING input level. (CN9-7th)

2.5 V - 3.3 V

(when nothing on the Starting Sensor)

b. Check the STARTING LED level on the

CONTROL board.

(1). IC24

(2). IC42

c. Check the STARTING LED level.

(CN9-6th)

1.9V - 2.6V

6. Replace faulty parts or cables.

7. Conveyor Motor or

mechanical parts (gear and

others) do not work properly.

1. Perform the

"Conveyor Motor"

test or

"Feed"

test

in Sec.

) to check whether the motor rota-

tion is transmitted to the Paper Feed Roller prop-

erly.

And check the gears' (that will transmit the motor

rotation) configuration.

2. Check and adjust the motor’s belt tension.

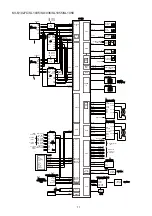

3. Check the following connection and soldering

condition.

(1) CN8 (CONTROL Board) to Conveyor

Motor

4. Monitor the following signals.

CN8- 1, 2, 3, and 4th pins

(See Fig. 10.2.3.)

5. Replace faulty parts or board.

Summary of Contents for KV-S1057C

Page 7: ...7...

Page 9: ...9 3 Location of Controls and Components 3 1 Main Unit...

Page 10: ...10...

Page 16: ...16 5 Section Views 5 1 Motor 5 2 Roller...

Page 17: ...17 5 3 Board and Sensor...

Page 31: ...31 7 3 8 Wiring of Upper Chassis...

Page 128: ...128 14 Exploded View and Replacement Parts List...

Page 133: ...133 14 3 Feed Tray Assembly 302 305 302 303 307 301 306 305 302 304 Feed Tray Assembly...

Page 188: ...Index 74 8 Operating Manual Table of Contents...

Page 255: ...PNQX6995ZA DD0914HS0 Panasonic System Networks Co Ltd 2014...