Chapter 4. Installation and maintenance

4.1 Power distribution

Installation and startup must only be carried out by qualified

personnel. The relevant country-specific electrical safety

codes and regulations (e.g., VDE, DIN) must be observed.

Before startup it is important to ensure that:

• The mains have been connected correctly and adequate

protection is provided against electric shock.

• The device can be switched off outside the power supply

according to EN 60950 regulations (e.g., by the line

protection on the primary side).

• All supply lines have sufficient fuse protection and are the

correct size.

• All output cables are the correct size for the maximum

device output current or have separate fuse protection.

• Adequate convection is available.

After installation the terminal area must be covered to

provide sufficient protection against unauthorized access

to live parts. This is ensured by installing the system in the

control cabinet or distributor box. For reliable and safe-to-

touch connections strip 7 mm (0.28 in.) from the connector

ends. The following cable cross sections can be used

(copper wiring recommended):

1

4

2

3

Figure 29: Phoenix Contact MINI-PS-100-240AC/24DC/C2LPS

I/O connections

4.1.1 Input

(1, figure 29)

The 100 - 240 V AC connection is made using the L and N

screw connections. The power supply in the top module

can be connected to single-phase AC networks or to

two external conductors for 3-phase networks (TN, TT or

IT network according to VDE 0100 T300/IEC364-3) with

nominal voltages of 100 - 240 V AC. The device must be

installed according to the specifications of EN 60950. It

must be possible to switch off the device using a suitable

disconnecting device outside the power supply. Note that

an all-pole disconnecting device must be provided for

2-phase operation using two external conductors for a

3-phase network. For this, line protection on the primary

side, for example, is suitable. Further device protection is not

required, as an internal fuse is present.

4.1.2 Output

(2, figure 29)

The power supply unit meets the requirements of NEC

Class 2. The 24 V DC connection is made using the “+”

and “-” screw connections on the screw connection 2. The

output voltage set upon delivery is 24 V DC and can be

adjusted from 22.5 to 26 V DC on the potentiometer 4. The

device is electronically short-circuit-proof and idling-proof.

In the event of an error, the output voltage is limited to a

maximum of 35 V DC. It should be ensured that all output

cables are the correct size for the maximum output current

or have separate fuse protection. The cable cross sections

in the secondary circuit should be large enough to keep the

voltage drops on the cables as low as possible.

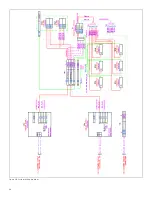

4.1.3 Wiring diagram

The control requires a single or redundant power source(s)

and safety ground connection. While the Ethernet switches

have built-in terminals to accept two redundant diode-

OR’d inputs of 18–36 V DC, the DPU’s are powered though a

separate diode redundancy module. See detailed wiring

diagram in figure 30 below for more details.

CAUTION!

Make sure all electrical connections are

correct and secure.

Solid

[mm2]

Stranded

[mm2]

AWG

Torque

[Nm]

Torque

[lb in]

1 – Input

0.2 - 2.5

0.2 - 2.5

25 - 14

0.5 - 0.6

4.4 - 5.3

2 – Output

0.2 - 2.5

0.2 - 2.5

25 - 14

0.5 - 0.6

4.4 - 5.3

3 – Signal

0.2 - 2.5

0.2 - 2.5

25 - 14

0.5 - 0.6

4.4 - 5.3

Table 8: Wiring specification for MINI 24 VDC power supply

37

Summary of Contents for flare.IQ Generation 2

Page 1: ...flare IQ Generation 2 Operation and maintenance manual...

Page 2: ...2...

Page 3: ...flare IQ Generation 2 Operation and maintenance manual 910 350 rev A June 2020 3...

Page 4: ...no content intended for this page 4...

Page 38: ...Figure 30 System wiring diagram 38...

Page 48: ...48...