D.

DRVR. & PASS COIL (mandatory) - The ignition system on this engine is a

multiple coil configuration called coil per plug. The ignition coil mounting bracket

is attached to the rocker cover. The secondary ignition wires are short compared

to a distributor ignition system wire. See Figure 6.21 & 6.22

E.

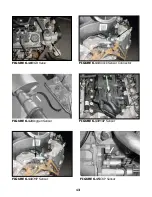

ECT (mandatory) - The (PCM) supplies a 5.0 volt signal to the Engine Coolant

Temperature (ECT) sensor through a resistor in the PCM and measures the

voltage. The voltage is high when the engine is cold. The voltage is low when the

engine is hot. The PCM calculates the engine coolant temperature by measuring

the voltage. The engine coolant temperature affects most systems the PCM

controls. See Figure 6.23

F.

EGR (optional) – An Exhaust Gas Recirculation (EGR), system is used to lower

oxides of nitrogen (NOx) emission levels. The EGR system accomplishes this by

feeding small amounts of exhaust gas back into the combustion chamber. High

combustion temperatures cause NOx. Combustion temperatures are reduced

when the air/fuel mixture is diluted with the exhaust gases. See Figure 6.10

G.

GROUND (mandatory) - These circuits are used to provide ground for the

various devises. Connect these wires under a bolt in the engine block,

transmission, or cylinder head. These are the grounds for the entire injection

system. For best results from your EFI system, be certain your grounding

surfaces are clean and your connections are secure.

H.

IAC (mandatory) - The purpose of the Idle Air Control Motor (IAC) is to control

engine idle speed. The IAC valve, mounted in the throttle body, controls the

amount of bypass air. See Figure 6.19

I.

INJ #1 - #8 (mandatory) – The Multec 2 fuel injector assembly is a solenoid

operated device, controlled by the PCM that meters pressurized fuel to a single

engine cylinder. An injector that has been sitting for more than 6 months will

need to be cleaned/ replaced as the varnish residue in the fuel will cause the

injector to stick closed. This will keep the injector from delivering fuel as needed

by the injection system. See Figure 6.16 & 6.17

J.

KNOCK (mandatory) – To control spark knock, a Knock Sensor (KS) system is

used. This system is designed to retard spark timing up to 20 degrees to reduce

spark knock in the engine. This allows the engine to use maximum spark

advance to improve drivability and fuel economy. See Figure 6.11

K.

LEFT & RIGHT O2 SEN. (mandatory) – The PCM uses the signal voltage from

heated oxygen sensors in a Closed Loop to adjust the fuel injector pulse width.

In Closed Loop, the PCM adjust fuel delivery to maintain an air to fuel ratio which

allows the best combination of emission control and drivability. See Figure 6.12

L.

MAF-IAT (mandatory) – The Mass Air Flow (MAF) sensor measures the

amount of air which passes through the sensor. The PCM uses this information to

determine the operating condition of the engine in order to control the fuel

delivery. A large quantity of air indicates acceleration. A small quantity of air

indicates deceleration or idle. See Figure 6.20

12