B-320-2-E

39

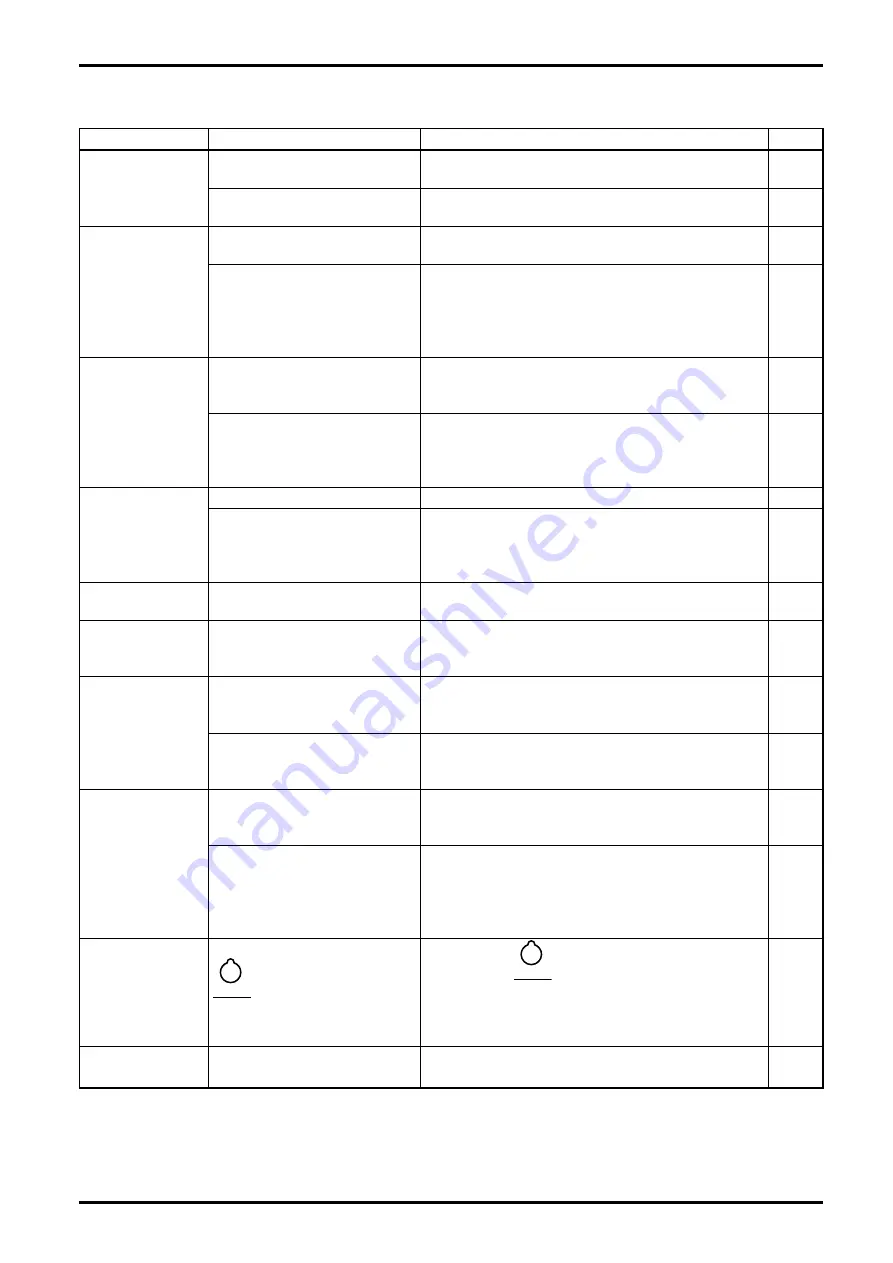

SYMPTOM

POSSIBLE CAUSE

CHECKOUT AND COUNTERMEASURE

Ref. page

10. Liquid leaks from

the pipeline.

Incomplete seals at pipeline

connections.

Retighten bolts at pipeline connections or replace

gaskets.

-

Incomplete seal in the rear cover

of flowmeter body.

Inspect flowmeter rear cover fitting bolts for tightness or

replace O-ring with new one.

32 to 35

11. Counts while

the shutoff valve

remains closed.

Leaks from shutoff valve or

pipeline connections.

Inspect shutoff valve and pipeline connections for leaks.

-

Air pockets exist between the

shutoff valve and flowmeter body;

the rotors keep a rocking motion

in response to pulsating pump

pressure.

Discharge the air to atmosphere.

-

12. Counter reading

too high.

Pulsation of the fluid causes

the rotors to move in a rocking

motion.

Provide a check valve and accumulator.

Influenced by external magnetic

fields. (The flow sensor picks

up external magnetic fields of a

motor, generator, etc.)

Isolate from external magnetic fields.

13. Counter reading

too low.

Air entrapped.

Discharge the air to atmosphere.

-

Influenced by external magnetic

fields (the flow sensor picks up

external magnetic fields of a

motor, generator, etc.)

Isolate from external magnetic fields.

4. "BATT" alarm

blinks.

Indicates a weak battery.

Referring to Sec. 10.2 "Battery Pack Replacement",

replace the battery pack early.

36

5. "BATT" alarm

blinks and

"ALM" stays on.

A low battery alarm. (The battery

is generally no longer serviceable

in this state.)

The meter is out of service until the battery is replaced.

Referring to Sec. 10.2 "Battery Pack Replacement",

replace with a new one.

36

16. Batch process

fails to stop

at the target

setpoint.

Trouble lies in the internal

assembly.

Does "OUT" go out and "END" light in the LCD at batch

setpoint? Monitor waveshapes according to Sec. 9.1

"Register Inspection.

7

29

Trouble lies in the solenoid valve.

Is the output (air signal) from solenoid valve switched

correctly at batch setpoint?

(With LW76E: OUT 1 OFF, OUT 2 OFF)

5

17. Batch process

stops while

metering is in

progress.

Single-acting shutoff valve:

Shutoff valve operating air

pressure has dropped.

Has the air pressure dropped below the operating

pressure range?

-

Intermittent interruption of the

process fluid flow during a batch

process causes missing pulse

detection and shutoff valve

closure signal generation.

Make sure of process fluid flow.

0

18. Cannot reset the

alarm.

RESET

▲

button is not pushed in as

far as it will go.

If pressing the

RESET

▲

button fails to reset, repeat the

same procedure with internal buttons in the internal

assembly. If this proves to be successful, trouble lies in

the external buttons or in the internal assembly.

16

19

19. LCD display is

dim.

The register is located higher

than the operator's eye level.

You can best view this LCD from above. Adjust its

installation height for best readability.