Installation and operating manual for WATERFRIEND -Chlorine MRD-3 Page 7

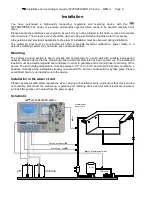

Measurement water pump

The dosing "WATERFRIEND" requires a continuous supply of sample water with a water amount of 0.3 to

1.0 liters per minute. When using filter pumps with variable displacement or in unfavorable pressure

conditions of the eventual use of a sample water pump must be checked.

General informational installation in the water circuit

•

Before carrying out initial start-up, ensure that the injection valves open and close reliably.

•

All hoses must be routed free of kinks.

•

Avoid routing hoses over sharp edges.

•

Connect all hoses carefully and check to ensure that they are tightly fitted to their connections.

•

Avoid unnecessarily long hose lengths.

•

Hoses may not be routed directly over pipes carrying heat or over other devices.

Electrical connection

The controller must be mounted protected against moisture in accordance with its protection class. The

device must be powered via a multi-pole main switch with a contact opening width of at least 3mm and a

residual current circuit breaker with I

FN

≤

30mA. The device must be isolated before opening the housing.

Electrical power supply connections, in addition to alignment and service work, may only be carried

out by approved electricians. The attached circuit diagrams and all applicable safety regulations

must be observed.

Low-voltage cables

Low-voltage cables may not be routed together with three-phase or alternating current cables in one cable

duct. Routing of low-voltage cables in the vicinity of three-phase or alternating current cables should

generally be avoided.