Regular Payload Series-Hardware Installation Manual TM5 Series

21

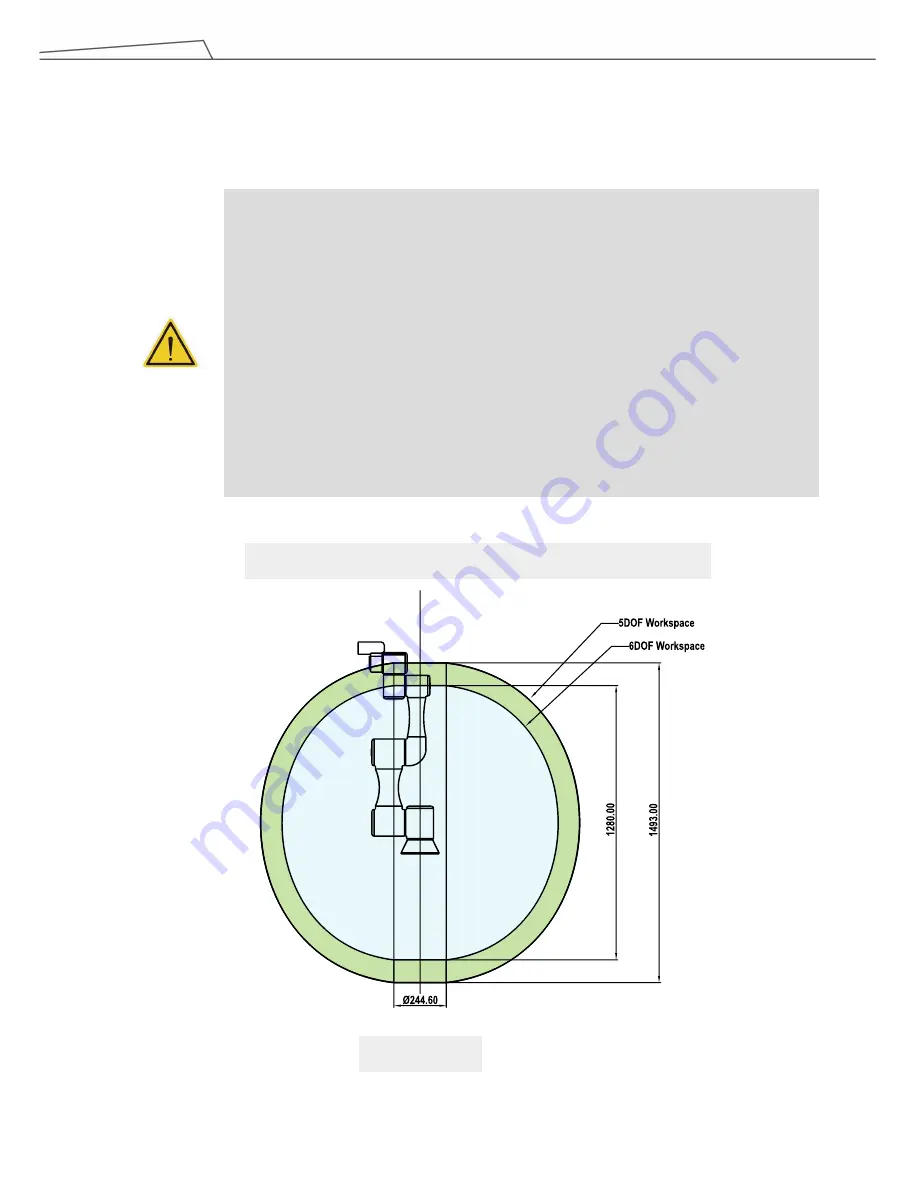

4.2.1.3 Range of Motion

The working spherical (radius) range from the base is 700 mm for the TM5-700 series and 900 mm for

the TM5-900 series.

DANGER:

With the exception of an individual being in full control of robot motion during hand-guiding,

personnel shall be outside the safeguarded space when the robot is in motion while in manual

mode (i.e.teaching).

The emergency stop on the robot stick shall be readily accessible during manual mode. At

least one emergency switch is installed outside of the motion range of the robot. When no

motion limit is set for the robot, the motion range of the robot is equal to the maximum motion

range of the robot arm. You can set a motion limit to avoid the situation whereby all operations

have to be out of the maximum motion range of the robot arm.

The robot stick should be placed in an area that the robot cannot reach. The user should also

make sure that the movement of the robot will not be within any area where personnel will

enter to press any buttons on the robot stick.

TM5-700 / TM5M-700 Movement Range Diagram

Side View