OIL-HYDRAULIC PRESSES WITH TWO UPRIGHTS

OPERATION AND MAINTENANCE MANUAL

40

7.12

ENCODER

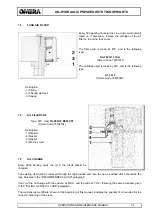

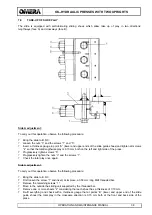

The encoder is a position transducer used in the presses

to detect the slide and blank-holder cushion stroke.

The machine is fitted with two identical encoders for this

purpose; the functioning principle of the slide encoder is

illustrated by the drawing given here.

One cam, which activate two limit-switchs, is used to the

stop the machine in the event of slide overstroke; this

cam act as safety devices and under no circumstances

should they be moved.

The mechanical application of the cushion encoder differs

from that of the slide encoder since it does not involve the

use of the P.M.B. overstroke micro-switch.

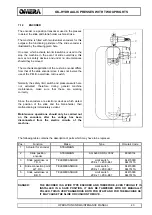

Normally the safety limit switch and pressure-switch are

not activated, therefore during general machine

maintenance, make sure that these are working

correctly.

Since the encoders are electronic devices which detect

the position of the slide and the blank-holder, their

malfunctioning is immediately evident.

Maintenance operations should only be carried out

on the encoders after the voltage has been

disconnected from the electric circuits of the

machine.

The following table contains the description of parts which may have to be replaced.

Pos.

Function

Make

Type

Omera’s Code

1

Actuator for encoder

STEGMANN

2

Slide position

encoder

STEGMANN

AG 626 XSR SL 3002

8832010L

3

Slide overstroke at

T.D.C.

TELEMECANIQUE

Limit switch

ZCK-J1 + ZCK-E67

84415000

8441511A

4

Slide connection point

at T.D.C.

TELEMECANIQUE

Limit switch

ZCK-J1 + ZCK-E67

84415000

8441511A

5

Slide overstroke at

B.D.C.

TELEMECANIQUE

Limit switch

ZCK-J1 + ZCK-E67

84415000

8441511A

DANGER:

THE ENCODER IS A WIRE TYPE ENCODER AND THEREFORE, EVEN THOUGH IT IS

INSTALLED IN A SAFE POSITION, IT CAN BE TAMPERED WITH OR MANUALLY

PULLED. THIS IS VERY DANGEROUS BOTH FOR STAFF AND FOR THE MACHINE AS

IT MAY CAUSE THE SLIDE OR CUSHION TO MOVE.