OIL-HYDRAULIC PRESSES WITH TWO UPRIGHTS

OPERATION AND MAINTENANCE MANUAL

13

4.2

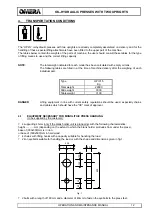

PROCEDURE FOR UNLOADING FROM THE MEANS OF TRANSPORT

The machine is transported lying on its side, therefore, proceed as follows to unload the machine:

?

fasten the two eye-bolts to the feet “1” (front and back), using the 40mm diameter bolts.

?

attach the lifting chains to these eye-bolts and to the lifting points “2” of the head (front and back), making

sure that they are tightened correctly.

?

unload the press from the lorry, lying it on the same side, onto the four resting shims which have already

been positioned near to the machine pit. Make sure that the machine’s parts are not damaged during

handling (e.g. oil-hydraulic pipes, electric cables, motors, etc.).

?

position two of the four shims near to the feet “3” so that the press can be straightened by pivoting on these

shims.

?

unhook the chains from the two eye-bolts fastened to the feet “1” and then remove the eye-bolts as well.

?

straighten the press slowly using the four chains hooked, in groups of two, to the lifting points of the head

“2” (front and back) and by pivoting on the feet “3”.

?

before straightening the press completely, place the other two shims (now freed from the weight of the

machine) under the feet “1” so that the blank-holder unit protruding in the lower part is not damaged.

?

once the machine has been straightened, hook the chains to all four lifting points of the head (“2” and “4”,

front and back) and place the machine in the foundations.