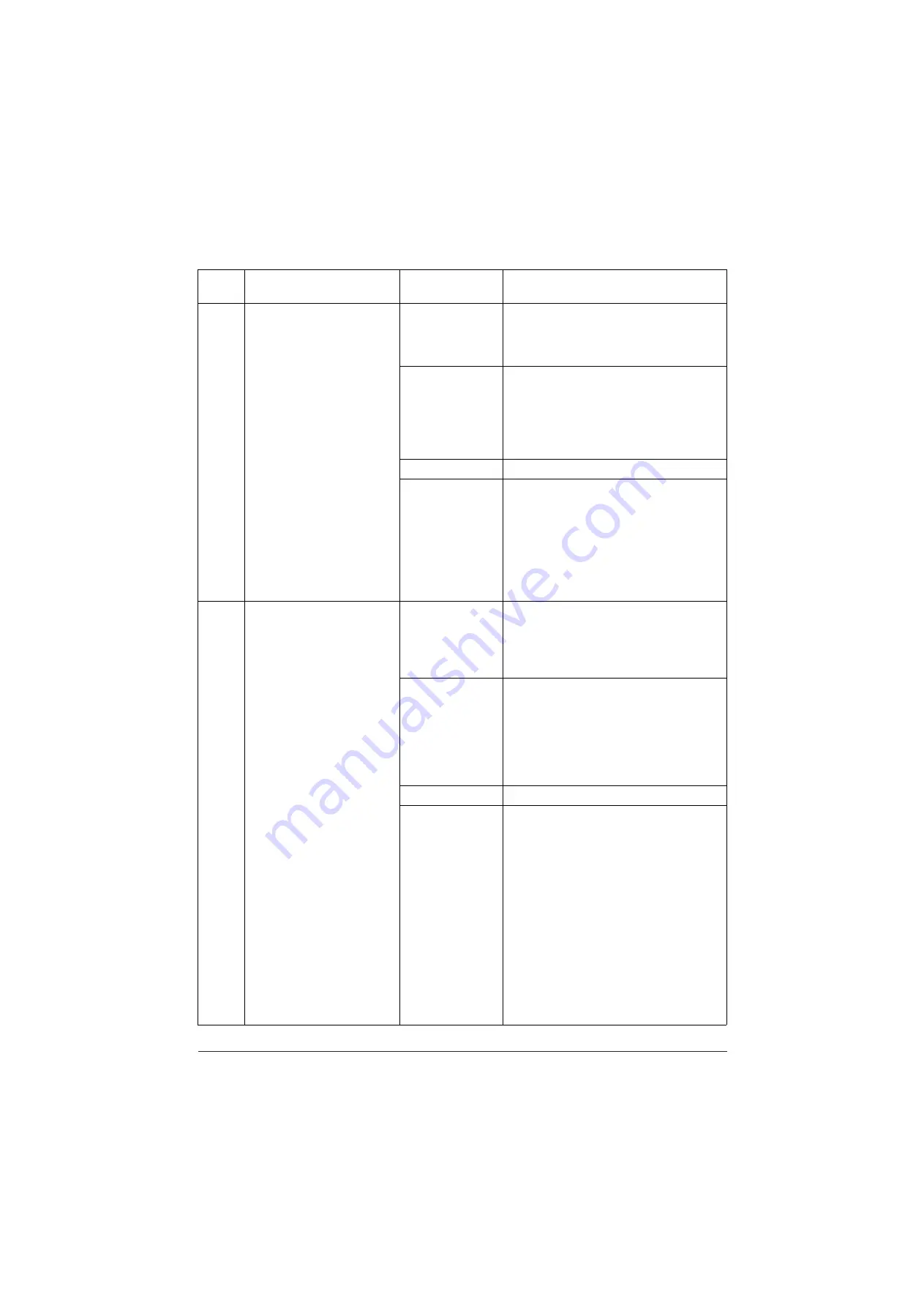

2NP

1-4-24

2111

Developer motor K startup

error

Developer motor K is not sta-

bilized within 3 s since the

motor is activated.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity of the connector cable. If necessary,

replace the cable.

Developer motor K and engine PWB (YC17)

Defective drive

transmission sys-

tem.

1. To check the motor operation, execute

DLP(K) by U030 (see page 1-3-34).

2. Check if the rollers and gears rotate

smoothly. If not, grease the bushings

and gears. Check for broken gears and

replace if necessary.

Defective motor.

Replace the Developer motor K.

Defective PWB.

1. Check the engine software and upgrade

to the latest, if necessary.

2. Replace the engine PWB and check for

correct operation (see page 1-5-33).

2112

Developer motor YCM

startup error

Developer motor YCM is not

stabilized within 3 s since the

motor is activated.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If neces-

sary, replace the cable.

Developer motor YCM and engine PWB

(YC16)

Defective drive

transmission sys-

tem.

1. To check the motor operation, execute

DLP(YCM) by U030 (see page 1-3-34).

2. Check if the rollers and gears rotate

smoothly. If not, grease the bushings

and gears. Check for broken gears and

replace if necessary.

Defective motor.

Replace the Developer motor YCM.

Defective PWB.

Replace the engine PWB and check for cor-

rect operation (see page 1-5-33).

Code

Contents

Causes

Check procedures/

corrective measures

Y1

16

1

41-8

Se

r

vice Manual

Summary of Contents for d-Color MF2552 plus

Page 1: ...SERVICE MANUAL Multifuction Digital Copier d Color MF2552 plus Code Y116141 8...

Page 4: ......

Page 10: ...This page is intentionally left blank...

Page 24: ...Y116141 8 Service Manual...

Page 86: ...2NP 1 1 2 62 This page is intentionally left blank Y116141 8 Service Manual...

Page 298: ...2NP 1 3 212 This page is intentionally left blank Y116141 8 Service Manual...

Page 458: ...2NP 1 5 56 This page is intentionally left blank Y116141 8 Service Manual...

Page 482: ...2NP 2 1 22 This page is intentionally left blank Y116141 8 Service Manual...

Page 540: ...2NP 2 3 48 This page is intentionally left blank Y116141 8 Service Manual...

Page 569: ...Installation Guide DP 770 B Document processor DP 772 Document processor Installation Guide...

Page 605: ...DP 773 Document processor Installation Guide...

Page 631: ...PF 791 500 x 2 Paper feeder Installation Guide...

Page 639: ...PF 810 3000 sheets deck Installation Guide...

Page 652: ...DF 770 D Document finisher Installation Guide...

Page 670: ...AK 740 Bridge unit Installation Guide...

Page 672: ...PH 7A C D Punch unit Installation Guide...

Page 693: ...DT 730 B Document tray Installation Guide...

Page 695: ...5 2013 5 302LC56750 01 H F G D D 6 4 3 7 E C D D M4 8 M4 8 M4 8 M4 8...

Page 696: ...FAX System W B Installation Guide...