Oki Data CONFIDENTIAL

44871001TH Rev.6

3-11

3. MFP INSTALLATION

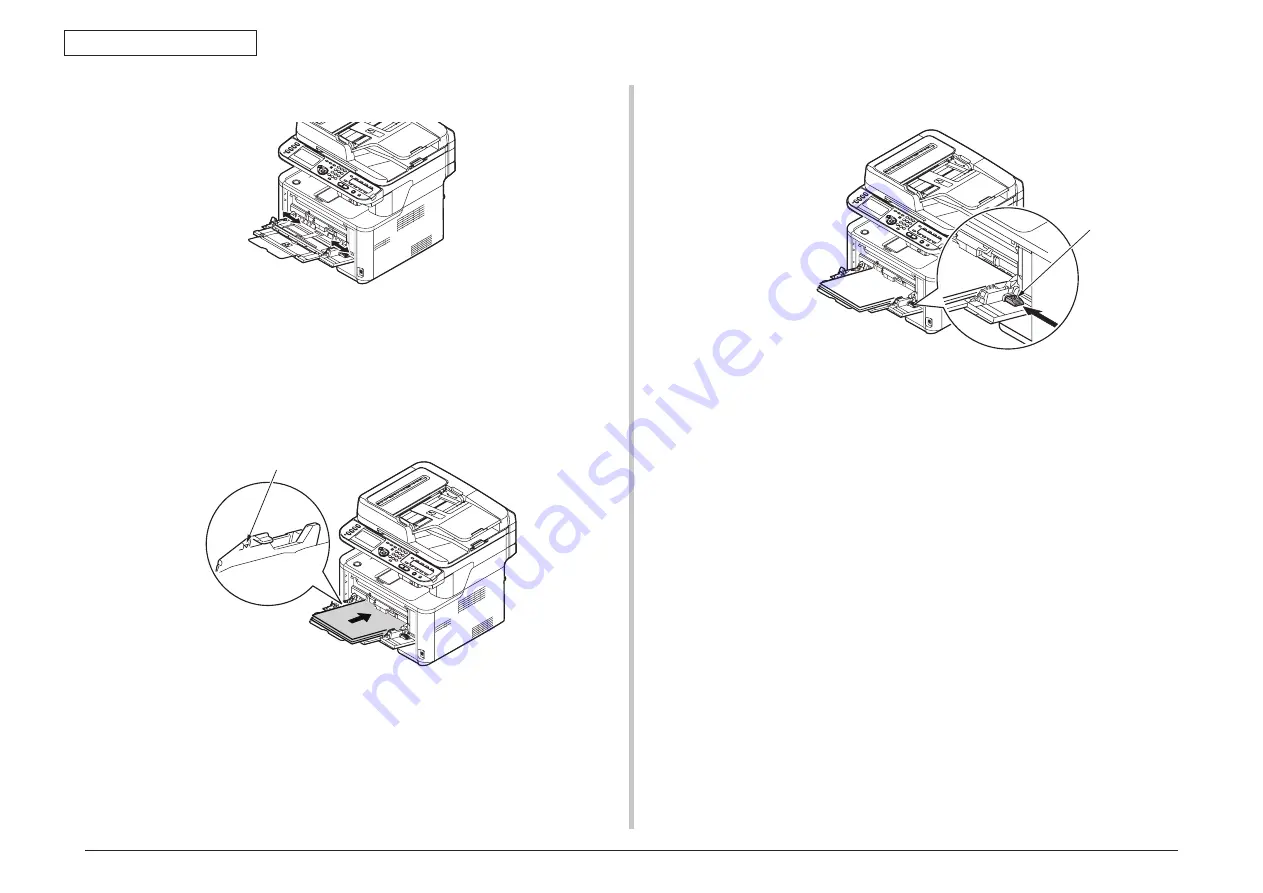

(4) Adjust the manual feeding paper guide to the width of paper to be loaded..

(5) Insert the paper with the print side face up until its edge touches the paper feed

entrance.

Note!

Do not load paper above the fill line.

(6) Press the Set button.

Register the loaded paper on the machine.

Proceed to "Configuring the Tray Settings".

Note!

•

Do not load paper of different sizes, types or weights at the same time.

•

When adding paper, remove the paper on the MP tray and straighten the

edges of both stacks of paper, and then load them again.

•

Do not put anything other than paper for printing.

Memo!

When loading envelopes on the MP tray, load them face up with the

orientation as stated below.

- You envelopes (Monarch, Com-9, Com-10, DL and C5) are loaded with

the flap folded and the flap should come to the right side to the feeding

direction.

Set button

Fill line

Summary of Contents for MB461MFP

Page 1: ...MB461 MB471 MB491 MB491 MB491 LP MPS4200mb MPS4700mb Maintenance Manual 031314C ...

Page 72: ...Oki Data CONFIDENTIAL 44871001TH Rev 6 3 21 3 MFP INSTALLATION Sample MB471 Sample MB491 ...

Page 114: ...44871001TH Rev 6 4 36 Oki Data CONFIDENTIAL 4 REPLACEMENT OF PARTS ...

Page 138: ...Oki Data CONFIDENTIAL 5 LUBRICATING POINT 5 1 Lubrication point 5 2 ...