OBO Bettermann

48 | EN

Installing the isCon® system

5 5

Routing the isCon

®

conductor

When routing the isCon

®

conductor to the forwarding conductor system,

observe the following information:

– The complete isCon

®

conductor must be located in the protection area

of the lightning protection system.

– The black cables may not be routed in the earth. They may not be

painted. Instead, use the grey isCon

®

ProPI 75 LGR cable.

– Only use the accessories for fastening (see section 3.4.3 on page

18).

– The forwarding connection of the isCon

®

conductor may only be made

using the isCon

®

connect connection elements of the respective is-

Con

®

conductors.

– An isCon

®

conductor may not be extended.

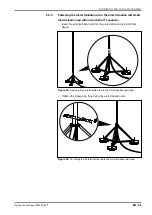

– When making route changes, maintain the minimum bend radius (see

Table 2 on page 10).

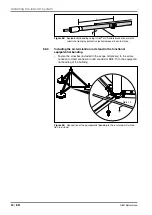

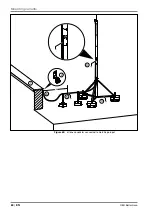

– Route the isCon

®

conductor in such a way that it cannot be damaged

by sharp-edged objects.

– If the isCon

®

conductor is damaged, the entire section must be re-

placed, as otherwise the correct function cannot be guaranteed. This

does not apply to the ProPlus 75 isCon

®

conductors. The ProPlus 75

variants may not have any damage or interruptions to the grey jacket

and/or rubber jacket. The exterior conductive layer may not be dam-

aged or interrupted.

– Ensure that the cable is connected to the equipotential bonding of the

structure as described in section 5.6. Create additional equipotential

bonding for metallic objects which cross or run in parallel (see section

5.6.4 on page 55).

– Special measures must be complied with for routing in potentially

explosive areas (see “„4.4 Installation in potentially explosive areas“ on

page 25).

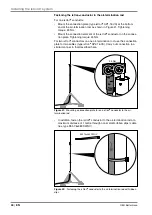

– No point of the jacket of the isCon

®

conductor may come into contact

with parts carrying lightning current.

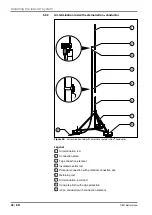

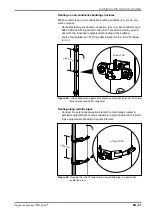

– Elements fastening the isCon

®

conductor may be spaced a maximum

of 1 metre apart.