XGN Handbook

Page 12

O

PERATION

When the burner is switched on the start procedure

begins: -

The MBC completes a series of internal tests.

Both the air and gas motors check their reference

positions.

The air damper moves to the high fire position.

Air pressure switch is checked to ensure that it is

in the open position.

The flame monitor checks if flame is present.

If the above is successful, the fan begins the pre-

purge.

During the pre-purge and thereafter the air

pressure switch monitors the air pressure.

The gas servo motor opens fully, above 90° and

then closes to the ignition position.

After the pre-purge period, the air damper moves

to the ignition position.

At the start of the ignition and thereafter the gas

pressure switch checks the gas pressure.

Ignition takes place and the burner starts to fire.

C

OMMISSIONING

THE

B

URNER

Re-check that the electrical wiring is complete and

complies with all Codes and Standards. Check

fuses are fitted and correctly sized.

Re-check that the gas pipework is correctly

installed and there are no leaks.

Set the low gas pressure switch to just above the

minimum and the air pressure switch to minimum.

Check that the appliance is in a proper and safe

state to be fired.

Set the appliance controls to call for heat.

Check for Valve Closure

All gas train assemblies are fully leak tested before

despatch. A test of the individual gas valves is

difficult without specialised testing equipment.

However, the following check can be performed

to test the security of the valve system.

Fit a manometer to the test point at the inlet to

the upstream main safety valve. Open the main

upstream manual valve for a few seconds, then

close and secure the gas supply.

The manometer will detect any gas leakage and

will prove that gas is not leaking past the gas train.

If no drop in pressure is recorded then

commissioning can continue until a full valve

proving test is completed by the integrated proving

system.

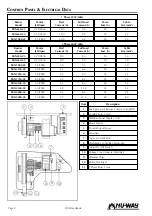

Gas Supply Pressures

Refer to the gas supply pressure graphs on pages

23 to 27 of this handbook. The supply pressure

must not exceed 100mbar. All pressures shown are

measured when the burner is at full firing rate.

Fit a manometer or other approved pressure

measuring instrument at the test point on the

upstream main safety valve. Open the main

isolating manual gas valve. Check there is adequate

gas pressure to enable commissioning to proceed.

Adjust IR Detector

Adjust the IRD to maximum sensitivity before start-

ing the burner. If the LED indicator is lit during the

start sequence, carefully adjust the sensitivity con-

trol until LED 1 extinguishes. No LED should light

up during the pre-purge phase.

Note:

Burner operating normally = both LED’s on

Burner in pre-purge phase = both LED’s off

For safety reasons the sensitivity must not be set

higher than necessary

E

STABLISHING

M

AIN

F

LAME

Measuring Gas Flow

In the following sections, reference is

made to checking gas flow rates at the

gas meter. This is the most accurate

method of determining throughputs and

should always be used whenever

possible.

Information regarding the burner head

gas pressures is shown on pages 23 to 27. These

are intended as a guide to initial burner settings,

but should not be relied upon to offer proof of

actual throughputs.

IMPORTANT

After each adjustment, gas flow rate

and flue gas analysis should be checked.

ALWAYS

use approved test equipment.

NEVER

rely on a visual inspection of the flame as

a guide to combustion quality.

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...