XGN Handbook

Page 14

Use the (-) key to move the display backwards from

P0.

To alter the value of any gas setting, move to the

required display point (P9,P1 or P0) and use the

(1) key in conjunction with the (+) or (-) keys.

To alter the value of any air setting, repeat the

above procedure but using the (2) key in

conjunction with the (+) or (-) keys.

The Low Flame point P1 cannot be set at a higher

value than the High Flame point P9.

The initial burner setup is now complete.

Table of Available Gas and Air Settings.

Firing the burner

Scroll through to the GAS EL display by pressing

(+), close the burner control circuit. The burner

will now start.

The display will show a number scrolling down

whilst pre-purge takes place, eventually the burner

will fire at position P0 and will remain at this

position until further actions take place.

Switch the burner off and check the fan motor

rotation, which should be anticlockwise, viewed

from the motor end. If the rotation is incorrect,

please refer to

‘Fault Finding’

to correct it.

Restart a fresh from entering the pass code and

allow the burner to fire at position P0.

•

Press (+) to move the control point to P1,

the Low Fire position.

•

Check that the gas pressure is not excessive.

•

Visually check for a clean, safe and stable

flame, adjusting the air damper to suit if

necessary.

Press key (2) to move to the next number, the

second line will start to flash. To enter this number,

(nine) in this illustration, press (+) key nine times,

or the (-) key once (10-9)=1. Again the flashing

line will drop to indicate it has been recorded.

Press key (2) to move to the next number, zero,

the third line will start to flash. Zero requires no

action therefore move to the next number, (four).

Continue this procedure until all the numbers have

been entered.

When the last number has been recorded, press

the acknowledgement key. The procedure is

complete.

If required, pressing key number (1) will return the

flashing line to the previous position.

Commissioning Procedure

The Nu-way XGN burner has been delivered with

initial gas and air settings. These have been applied

to the burner during the test and inspection phase

of its manufacture. Whilst these settings may

enable the burner to operate, they are not

intended to be final settings.

The commissioning procedure consists of the

following: -

•

Entering the pass code.

•

Reviewing the air and gas set points.

•

Firing the burner.

•

Commissioning the burner.

•

Completing the procedure.

Refer to page 13 for a functional description of the

Display unit.

Enter the pass code.

Initial settings for air and gas.

The MBC will calculate values for the intermediate

points P2 to P8.

Use the (+) key to move the display forwards from

P9 through P1 to P0.

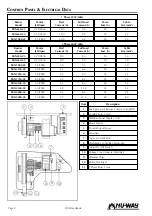

Point

Maximum Angle Minimum Angle

P0

P1+25.5°

0 or P1-25.5°

P1

P0+25.5° or P2

0 or P0-25.5°

P2

P1+25.5° or P3

P1

The same formlula applies to points P3 to P8

P9

P8+25.5° or 90° P8

Bu

P1

Bo

Bo

P9

Bu

Set

Point

Combus-

tion Air

Gas

Firing Rate

P9

65°

90°

High Fire

P1

15°

10°

Low Fire

P0

10°

5°

Ignition Position

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...