Page 21

XGN Handbook

Incorrect Rotation of Burner Motor

The Fan Motor rotates clockwise viewed from the

shaft end. If the motor is single phase, replace the

motor. If three phase, interchange any two phases.

Motor & Fan – Removal

Remove the control package cover and disconnect

the four gas train plugs from the MBC controller.

Remove the retaining screw securing the control

package to its mounting bracket.

Lift the complete control package from the

mounting bracket and rest it on top of the burner

casing.

All the motor securing devices will now be visible

and accessible.

Burner Motor Fails to Start

Check:

•

that the electrical supply is available and the

burner is correctly wired

•

all fuses for continuity and size

•

all control instruments are “calling for heat”

•

the MBC control is not locked out

•

The gas supply is not isolated

•

There is sufficient gas pressure

•

The gas pressure switch is correctly set

Starting Flame Failure Without Ignition

Check:

•

The glass envelope of the IR detector is clean

and correctly positioned

•

The IR Detector sensitivity and its wiring

•

The air pressure switch is set correctly

•

The electrode is correctly set and the porce-

lain is not cracked

•

The ignition transformer is not faulty

Starting Flame Failure Without Flame

Check:

•

The air setting is correct

•

There is sufficient gas under ignition

conditions

Ensure that the start rate gas flow

does not exceed 30% of the high

flame gas rate as measured at the

Gas Meter.

•

The gas valve(s) operate correctly

Burner Fails to Establish Main Flame

Check:

•

The gas butterfly is operating correctly

•

The combustion air is set correctly

•

There is sufficient gas

IR Detector Possible faults

If the LED’s light up during the pre-purge phase.

•

Sensitivity set too high.

•

Stray light.

•

Ignition spark visible to detector (directly or

reflection). Correct by preventing direct sight

of ignition spark.

•

Interference from ignition cable (lay cables

some distance apart, or possibly screen the

detector).

No indication from LED’s after establishment of

flame:

•

Incorrect or faulty wiring.

•

Sensitivity set too low.

•

Detector positioned wrongly (receives no

light).

•

Detector or viewing window dirty.

•

Defective detector.

6FH Error - Failure of the air servo motor

•

Isolate the burner from the power supply and

check the lead connectors at the motor and

controller for a positive location.

•

Disconnect the servo motor from the air

damper shaft. With the gas supply isolated

restart the burner and check the display runs

through the "Check servo drive" displays. If

6FH is reported, the servo motor and lead

should be replaced. Under no circumstances

attempt to dismantle the servo motor to at-

tempt repair.

•

Check that the air damper shaft rotates freely.

Check the damper blade runs clear of the

inlet casting in all positions. Check that the

bearings fitted at each end of the air damper

shaft run free and smooth. Clean and lubri-

cate the bearing surfaces with copper grease

if necessary.

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

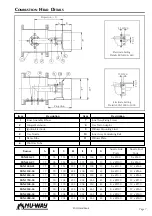

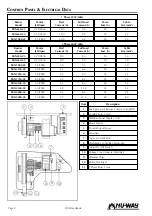

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...