XGN Handbook

Page 16

Setting the Low Gas Pressure Switch

Loss of gas pressure will cause the burner to switch

off. After a 2 minute delay the burner will reststart.

After two restarts the delay is increased to 1 hour.

This delay can be removed by electrically isolating

the burner and then reestablishing the power.

Remove the gas pressure switch cover and allow

the burner to establish main flame.

Slowly turn the adjustment dial on the gas pressure

switch clockwise until the flame is extinguished

and the burner shuts down. Turn the dial slowly

anticlockwise one division at a time until the

burner restarts and establishes main flame. Turn

the dial a further two divisions anticlockwise.

Replace the gas pressure switch cover.

F

INAL

C

HECK

Check that all the covers to components have been

replaced and that locking devices are properly

secured. Check that the appliance control

instruments are set to safe limits. On modulating

burner check and set the RWF40.

Commissioning is now complete

Switch on the electrical supply.

The burner will now operate until switched off.

a)

by controlling instruments of the appliance

b)

manually

c)

by power failure. Upon restoration of power,

the burner will restart automatically and

follow the normal sequence.

T

HE

RWF40 M

ODULATION

C

ONTROL

Basic display

The diagram below shows the RWF40 after

switching on the supply voltage. This condition is

called the basic display. The actual value and the

currently active set-point are shown here. Manual

operation, self-optimization, the operating

parameter and configuration levels can be activated

from here.

To change the working set point.

The operating display shows the actual pressure/

temperature of the boiler in red and the required

set point pressure/temperature beneath in smaller

green digits.

One quick press of the PGM button, the display

changes to show the set point as the larger red

digits and the SPI in the lower small green digits.

Alter the red display using the up/down buttons

to show the new required set point, press exit or

let the unit time out to return to the basic display

which should be the new set point figure.

K6

PGM

EXIT

SIEMENS

Landis & Staefa RWF40

Burner enable

Reduce output

Increase output

Manual

operation

Limit

comparator

Increase

value

Exit key

Process value

display (red)

Setpoint

value (green)

Reduce

value

PGM key

Summary of Contents for XGN Series

Page 4: ...XGN Handbook Page 4...

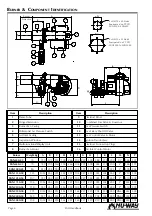

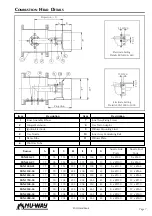

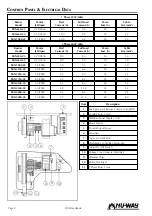

Page 23: ...Page 23 XGN Handbook XGN450 23 XGN650 23...

Page 24: ...XGN Handbook Page 24 XGN1000 25 XGN1150 38...

Page 30: ...XGN Handbook Page 30 NOTES...

Page 31: ...Page 31 XGN Handbook NOTES...