10-10

Page 11

2008-10-01

B. Safety Water Level Control Check

(1)

To ensure safe operation, the humidifier constantly monitors the back up float of

the humidifier and also performs float checks at regular intervals.

C. Self Diagnostic

(1)

This feature allows the user to activate various hardware elements within the

system to prove operational compliance.

D. Energy Efficient Blowdown Sequence – Unique to Nortec

(1)

Fill valve and blow down sequences are based on steam production and not time

of operation to increase efficiency of the unit. If the demand signal controls the unit

at the minimum output, of 25 lbs/hr, only 25% of 25 lbs/hr will be drained.

E. Internal Drain Water Tempering

(1)

The unique design for the internal Drain Water Cooler from NORTEC will ensure

water tempering at all times of the water going to drain. The fresh fill water will

completely mix with incoming hot water from the tank during blow down or drain

cycles and ensure water does not exit the system at more then 140ºF (60ºC).

(2)

When the “SMART” feature is enabled on the TC version, the temperature of the

tank is monitored and fresh cold water will be used only when drain water is above

140ºF (60ºC).

F. Capacity Turn Down

(1)

The GS humidifier is capable of full modulation of the output of each burner down

to 25 lbs/hr. For example on a four-burner system, such as the GS 400, the

turndown ratio is 6% of total output.

(2)

When the control signal requires less than 25 lbs/hr output, the internal controller of

the unit takes over with a unique time proportioning algorithm and to control the

output and modulate down to 0 lbs/hr.

G. GSTC Unit Networking

(1)

The new TC controller of the GS Series allows staged modulation through

networking of up to 10 units when higher capacities of steam require multiple units.

The modulating signal will be wired to the master unit and this one will control the

output of the other units for seamless modulation from 25 lbs/hr up to 6300 lbs/hr.

All units will be configured as master or staged. The operational range of each unit

will be set in the internal controller at the factory. A control modulation signal to the

master unit and a three-wire connection between each unit being staged is all that

is required.

2. CONTROLS

A.

Introduction

(1) The GSTC model features a backlit alphanumeric keypad for user interface, which

allows for adjustment of operating parameters and displays system operating status.

(2) The GSP model uses status indication lights.

Summary of Contents for GS Series GSP Indoor

Page 1: ...1503540 C GS Series GSTC GSP Indoor GSTC Outdoor Engineering Manual ...

Page 7: ...2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 8: ...10 00 Page 1 2008 10 01 10 00 PRINCIPLE OF OPERATION ...

Page 10: ...10 00 Page 3 2008 10 01 Figure 1 GS Indoor Series Figure 2 GS Outdoor Series ...

Page 11: ...10 00 Page 4 2008 10 01 Figure 3 GSTC Key Pad Figure 4 GSP Key Pad ...

Page 13: ...10 00 Page 6 2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 14: ...10 10 Page 7 2008 10 01 10 10 OPERATION ...

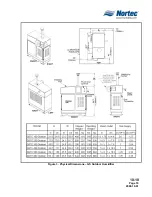

Page 17: ...10 10 Page 10 2008 10 01 Figure 3 Physical Dimensions GS Outdoor Humidifier ...

Page 21: ...10 10 Page 14 2008 10 01 Figure 4 GSTC GSP Indoor Clearance Figure 5 GSTC Outdoor Clearance ...

Page 23: ...10 10 Page 16 2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 24: ...10 20 Page 17 2008 10 01 10 20 MAINTENANCE ...

Page 27: ...10 20 Page 20 2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 28: ...10 30 Page 21 2008 10 01 10 30 OPTIONS ACCESSORIES ...

Page 35: ...10 30 Page 28 2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 36: ...10 40 Page 29 2008 10 01 10 40 SPECIFICATION ...

Page 44: ...10 40 Page 37 2008 10 01 THIS PAGE INTENTIONALLY LEFT BLANK ...