6

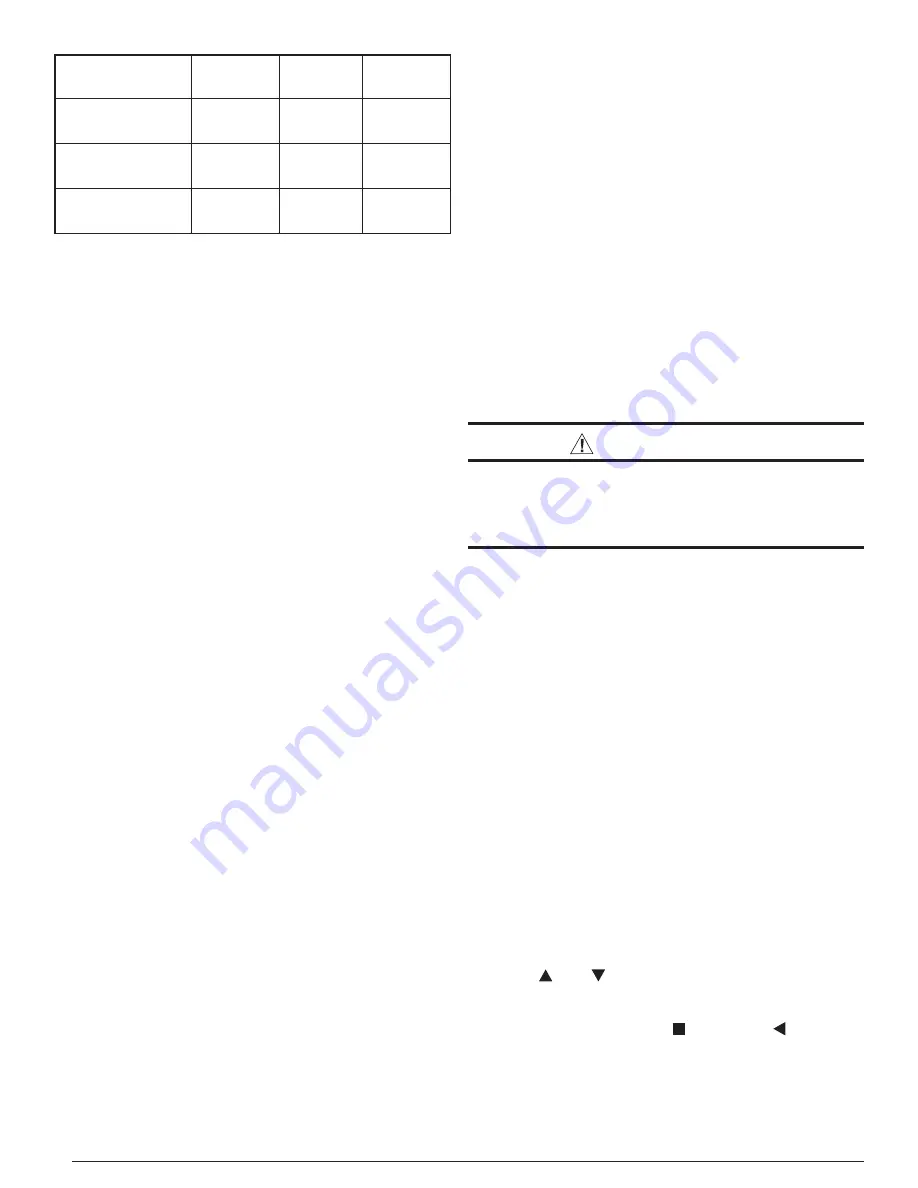

MODEL:

2 TON

(-024K)

3 TON

(-036K)

4 TON

(-048K)

Factory Charge

(for 15 ft. line set)

10.0 lbs

(160 oz)

10.5 lbs

(168 oz)

11.8 lbs

(188 oz)

Additional Charge

for 50 ft. line set

+ 1.1 lbs

(18 oz)

+ 1.1 lbs

(18 oz)

+ 1.1 lbs

(18 oz)

Additional Charge

for 100 ft. line set

+ 2.8 lbs

(44 oz)

+ 2.8 lbs

(44 oz)

+ 2.8 lbs

(44 oz)

Table 4. Refrigerant Charge Quantities

Alternate Procedure for Charging Heat Pump in

Cooling Mode (with outdoor temperatures above

60 °F) Based on Subcooling:

While charging based on weight is preferred, this method is

acceptable. Use this method when the outdoor temperature

is 60°F or higher to verify the correct charge in cooling mode.

The indoor temperature should be between 70°F and 80°F.

1. Connect the gauge manifold to the liquid and vapor service

valves (Figure 8).

2. Start the system in CHARGE MODE, COOLING. Allow

the system to run 15 minutes to stabilize.

3. Record the liquid refrigerant pressure in psig at the service

valve.

4. Record the liquid refrigerant temperature in °F at the service

valve.

5. Using the temperature value recorded, determine the

corresponding liquid refrigerant pressure from the upper

curve (for cooling) in the charging chart (Figure 9).

6. If the pressure measured in step 3 is less than the required

liquid refrigerant pressure determined in step 5, then

refrigerant needs to be added.

7. If the pressure measured in step 3 is greater than the

required liquid refrigerant pressure determined in step 5,

then the system is over-charged.

8. Add or remove charge from the system depending on the

measurements recorded. Allow the system to stabilize for

15 minutes before taking the next readings.

Alternate Procedure for Charging Heat Pump in

Heating Mode (with outdoor temperatures below

60 °F) Based on Subcooling:

Use this method when the outdoor temperature is 60°F or

lower to estimate the correct charge in heating mode. The

indoor temperature should be between 65° F and 75° F.

The preferred method of charging is by weighing in the

additional refrigerant required. If a charging scale is not

available, the correct charge can be estimated by this method.

Refrigerant can be stored in the receiver and accumulators

and result in an over-charged system. If it is necessary to

use this method, follow up service should be scheduled when

the temperature is above 60°F, and then charge should be

verifi ed in cooling mode.

1. Connect the gauge manifold to the liquid service valve and

suction service port located at the left side of the access

panel above the liquid service valve. See Figure 8.

2. Start the system in CHARGE MODE, HEATING. Allow the

system to run 15 minutes to stabilize.

3. Record the liquid refrigerant pressure in psig at the service

valve.

4. Record the liquid refrigerant temperature in °F at the service

valve.

5. Using the temperature value recorded, determine the

corresponding liquid refrigerant pressure from the lower

curve (for heating) in the charging chart (Figure 9).

6. If the pressure measured in step 3 is less than the required

liquid refrigerant pressure determined in step 5, then

refrigerant needs to be added.

7. If the pressure measured in step 3 is greater than the

required liquid refrigerant pressure determined in step 5,

then the system is over-charged.

8. Add or remove charge from the system depending on the

measurements recorded. Allow the system to stabilize for

15 minutes before taking the next readings.

SYSTEM SETUP USING THE IQ CONTROLLER

IMPORTANT:

It essential that the wires meant to provide 24 volts

to the outdoor unit are not mistakenly connected to

the communication terminals. Check again before

you apply power!

General

Power up the entire system with the iQ controller (thermostat)

installed in its base. The controller will be of use to the installer

for the following general purposes:

• Confi guring the system using INSTALLER SETTINGS

screens (required)

• Running system service tests (recommended)

• Using service information screens to examine and diagnose

system operation (very helpful, if needed)

• Setting options and features which are not typically used

or understood by the homeowner (recommended)

• Setting options and features with the homeowner’s oversight

in an effort to train him/her (suggested)

The following descriptions of the controller apply specifi cally

to software Version 5.0. A summary of the controller menu

structure is provided in Figures 10 & 11. NOTE: This guideline

is not intended to be a comprehensive substitute for proper

iQ Drive system training (required).

Screen Navigation

Moving between option categories on menu screens or

moving between possible values for any one option is done

using the and keys. The line or value with a dark

background behind the characters is considered “selected”.

In order to change a selected option in most screens, or to

save a changed value, use the key. Use the key to back

up into the previous screen in the menu/screen structure.

The Main Screen

The Main Screen is the normal display viewed on the

controller. It prominently shows room temperature and