13

When deration is completed, it is required that you measure

the gas input rate. This may be accomplished in the usual

way, by clocking the gas meter and using the local gas

heating value.

NOTE:

It will be necessary to check the

input rate using the actual heating value, (which will be

less) because the atmospheric pressure is also lower

than sea level. See Verifying and Adjusting the Input Rate

(page 15).

Conversion to LP/Propane

WARNING:

The furnace was shipped from the factory

equipped to operate on natural gas. Conversion

to LP/propane gas must be performed by

qualifi ed service personnel using a factory

supplied conversion kit. Failure to use the

proper conversion kit can cause fi re, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

Conversion to LP/propane is detailed in the installation

instructions provided with the conversion kit. Generally,

this will require the replacement of the burner orifi ces and

the spring found under the cap screw on the pressure

regulator.

The LP/Propane Gas Sea Level and High Altitude

Conversion Kit (P/N 904923) is an approved conversion

kit for LP/propane conversion at altitudes between zero

and 10,000 ft. above sea level. If the installation is above

2,000 ft., refer to Table 9 (page 26) to determine the correct

orifi ce size and manifold pressure. When conversion is

complete, verify the manifold pressure and input rate are

correct as listed in Table 9.

Please

follow the instructions

provided with the kit

.

ELECTRICAL WIRING

Electrical connections must be in compliance with all

applicable local codes. For electrical requirements, refer

to Table 2 (page 14) or the furnace nameplate.

WARNING:

To avoid electric shock, personal injury, or death,

turn off the electric power at the disconnect

or the main service panel before making any

electrical connections.

CAUTION:

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation. Verify

proper operation after servicing.

NOTE:

If replacing any of the original wires supplied with

the furnace, the replacement wire must be copper wiring

and have a temperature rating of at least 105° F (40° C).

Low Voltage Wiring

The thermostat must be installed according to the

instructions supplied by the thermostat manufacturer. The

thermostat must not be installed on an outside wall or

any other location where its operation may be adversely

affected by radiant heat from fi replaces, sunlight, or lighting

fi xtures, and convective heat from warm air registers or

electrical appliances.

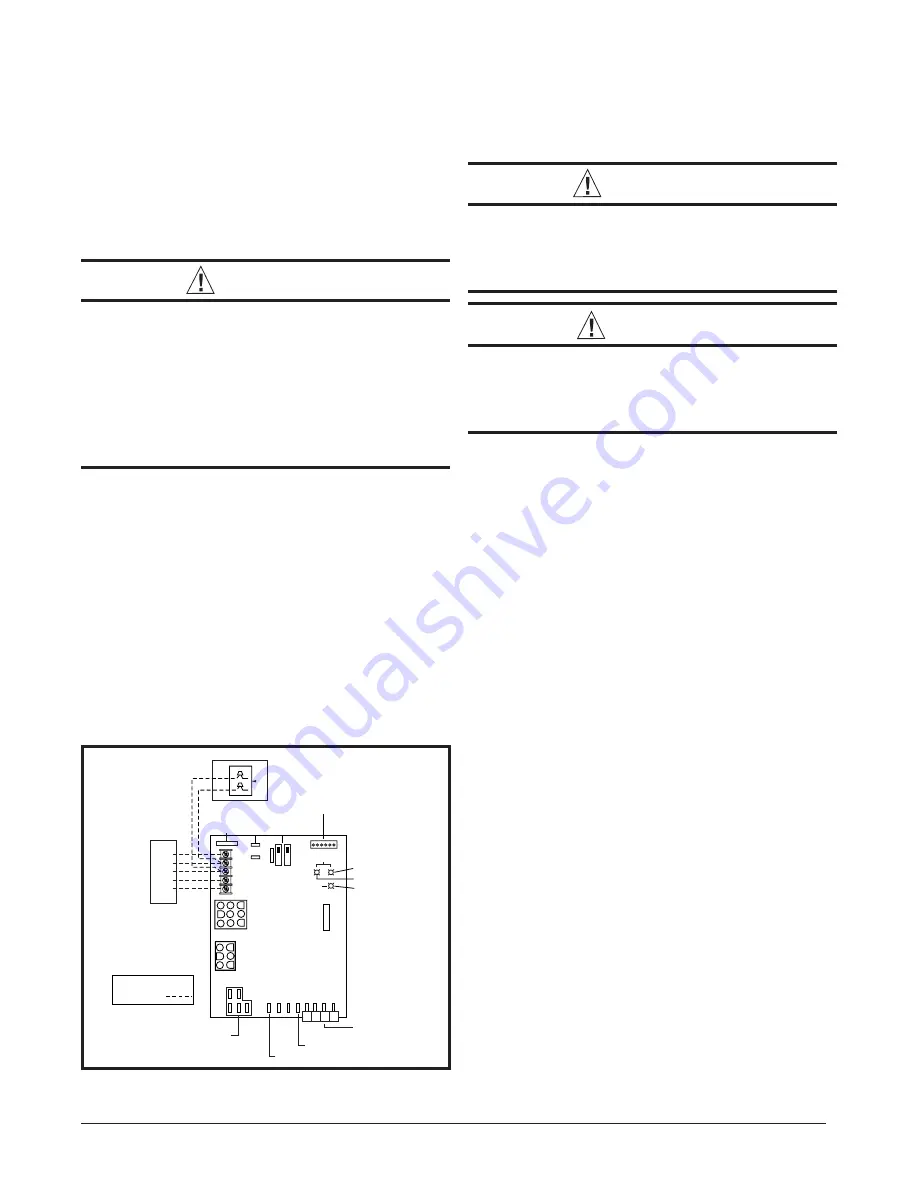

Low voltage connections (24 VAC) from the thermostat

are wired to the terminal strip on the integrated control

in the furnace. See Figure 11 for proper connections for

heating only (two-wire) and heating/cooling (four-wire)

applications. Recommended minimum wire gauge for

thermostat wiring is shown in Table 2.

NOTE:

Set the heat anticipator according to the instructions

supplied by the thermostat manufacturer.

To determine the

heat anticipator setting, perform the following steps:

1. Add the current draw of the system components; or

2. Measure the current fl ow on the thermostat

R

-

W

circuit

after the circulating blower motor has started.

Line Voltage Wiring

It is recommended that the line voltage (230 VAC) to

the furnace be supplied from a dedicated branch circuit

containing the correct fuse or circuit breaker for the

furnace (Table 2).

IMPORTANT NOTES:

An electrical disconnect must be installed readily

accessible from and located within sight of the

furnace. Any other wiring methods must be acceptable

to authority having jurisdiction.

Figure 11. Low Voltage Field, Four-wire

Heating/Cooling Applications

RCY

G

W

STATUS

FLAME

GREEN

RED

180

COOL

HEA

T

120

90

60

YELLOW

BLOWER

OFF

DELAY

LO

W

ML

MH

HIGH

EA

C

L1

XFMR

HUM

COM

SPEED

SELECT

3 AMP

FUSE

24V

5

NEUTRALS

ROOM

THERMOSTAT

A/C CONDENSING UNIT

CONDENSING UNIT

CONTROL BOX

EXPANSION PORT

(MOTOR CONNECTION)

FIELD WIRING

LOW VOLTAGE

CONNECTION

R

C

Y

G

W

NOTE: The “Y” terminal

on the control board

must be connected to

the thermostat for

proper cooling mode

operation.

Connect

R & W

For Heating

Only

2

ELECTRONIC AIR CLEANER

MOTOR SPEED TAPS

(NOT USED)

HUMIDIFIER TAP

NEUTRAL LEADS

6

3

4

1

7

8

9

5

2

6

3

4

1

FA

N

Summary of Contents for G7XA Series

Page 2: ...2...

![Goodman [A/G]PG Service Instructions Manual preview](http://thumbs.mh-extra.com/thumbs/goodman/a-g-pg/a-g-pg_service-instructions-manual_2243406-01.webp)