6 - MAINTENANCE

Fan and alternator drive belt

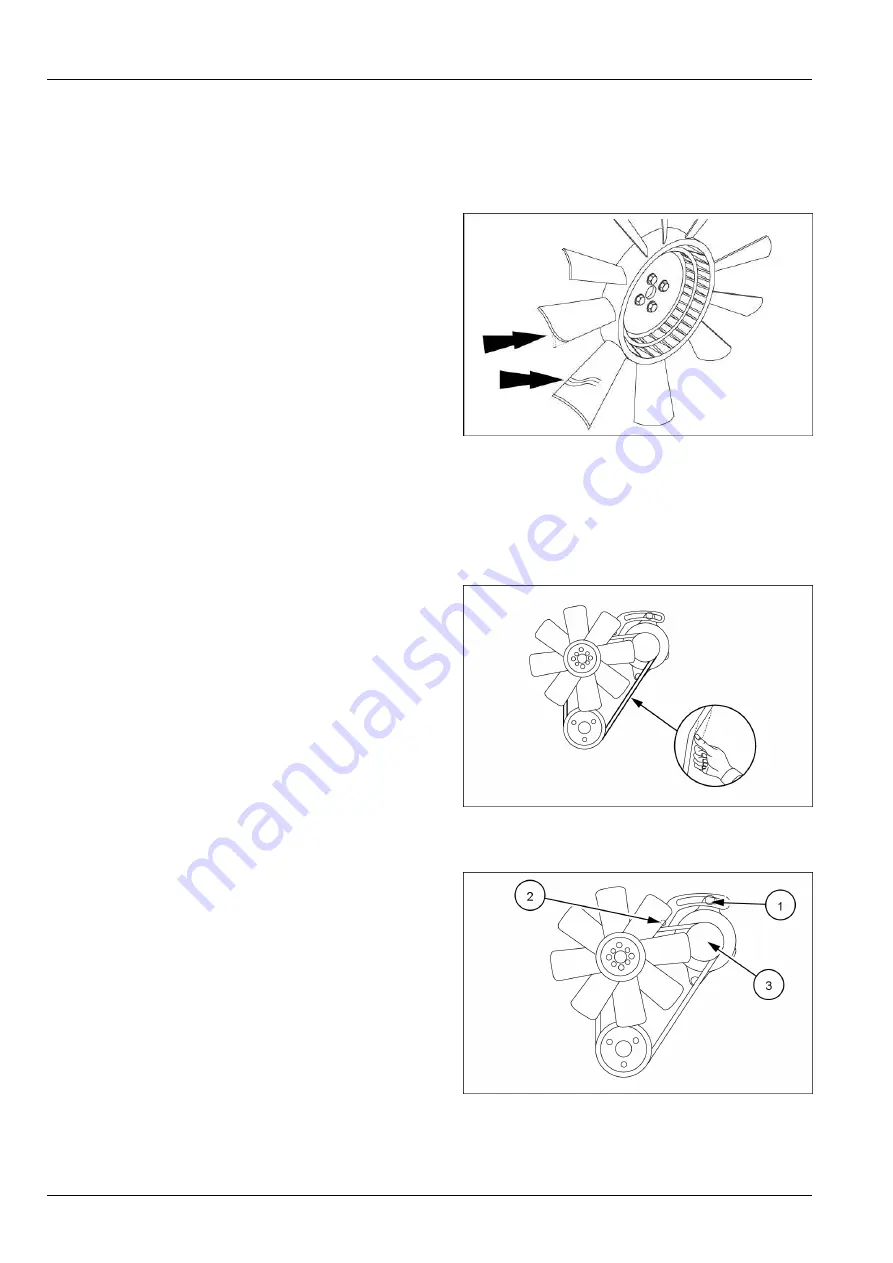

Inspection of fan

Inspect the fan every

10 h

or every day.

Perform a visual inspection of the fan for cracks, loose

rivets, and bent or loose blades.

SMIL16MEX0436AA

1

Inspection of belt tension

Check the belt tension every

10 h

or every day.

NOTICE:

operating the engine with loosened belt may cause over heat of the engine or insufficient charging of the

battery due to slipping belt in its housing.

1. Apply finger pressure of about

10 kg

(

22.0 lb

) at the

midpoint of the belt, between the alternator pulley and

the crankshaft pulley, while the engine is shut down and

the starter key is removed.

2. Belt deflection should be about

7 – 9 mm

(

0.3 – 0.4 in

).

NOTE:

check any indication of damage on the pulley or belt

due to wear. Check thoroughly to make sure that the belt

is correctly engaged to groove of the pulley. The belt must

be replaced if it is elongated, it has cracks or it is worn out.

SMIL16MEX0418AA

2

Adjustment of belt tension

1. Loosen the adjusting bolt

(1)

and the mounting bolt

(2)

.

2. Rotate the alternator

(3)

to obtain the correct value of

tension.

3. Tighten the mounting bolt

(2)

and the adjusting bolt

(1)

.

SMIL16MEX0419AA

3

6-24

Summary of Contents for E26C

Page 56: ...2 SAFETY INFORMATION 2 36 ...

Page 68: ...3 CONTROLS AND INSTRUMENTS Footrest SMIL19MEX0775BA 17 3 12 ...

Page 106: ...3 CONTROLS AND INSTRUMENTS 3 50 ...

Page 142: ...5 TRANSPORT OPERATIONS 5 8 ...

Page 218: ...6 MAINTENANCE 6 76 ...

Page 222: ...7 TROUBLESHOOTING 7 4 ...