NENO LEADX Ultra Manual

© NENO-CNC Schweiz 2023

Seite | 10

Required tools

We recommend a set of tools needed to assemble the NENO LEADX Ultra. Of course, You can also

use complementary tools.

1.

Allen key set

2.

Wrench or Ratchet Set

3.

Various screwdrivers

4.

Possibly M5 thread cutter for recutting

5.

Square ruler

6.

Linear guides alignment tool (included)

7.

Retaining ring pliers

8.

Grease gun for linear drives and ball screws

9.

Grease to grease gun

Notes on assembly

10.

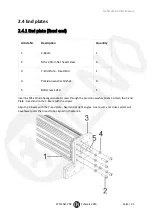

This guide is a generalization. Photos and graphics refer to the 1000 x 1000mm version of the

NENO LEADX Ultra. The manual also works without problems with the other two machine

sizes offered.

11.

At each step, first place all components listed in the respective BOM in front of you to get an

overview.

12.

In each case, it is specified whether an assembly must be built 2x. Also whether it is built

identically or mirrored, is highlighted in the instructions.

13.

For the accuracy of the machine, it is particularly important to measure each angle with a

stop angle to guarantee 100% perpendicularity before screws are fully tightened.

14.

If an M5 thread has been forgotten, please cut it with an M5 thread cutter.

15.

If you have a dial gauge, please run all linear guides with it to guarantee a completely flat and

rectangular machine.

16.

The connection of ball screw to fixed bearing is often ground to very minimal tolerances. If

the ball screw cannot be inserted into the fixed bearing with light pressure, take a sandpaper

with a fine grain size and carefully grind some material from the contact surface. Then

remove any residue.

17.

The ball screw can be too short or too long after fixing in the fixed bearing to attach the snap

ring in the loose bearing. The ball bearing, which is located in the loose bearing, can be easily

moved in the loose bearing by 1-2mm in both directions using a nut from a socket wrench set

and a rubber hammer.