2 - 24

2.5

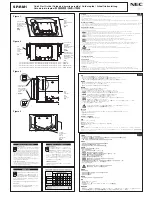

Inspections (In normal mode)

2.5.1

Electrical performance

Inspect the electrical performance after confirming that the contrast is set to MAX and the

bright is set to center (by pressing (-) (+) buttons simultaneously).

After inspection, carry out FACTORY PRESET operation.

2.5.1.1

Withstand voltage

There must be no abnormality when 1500VAC is applied for two seconds between both ends of

the AC input terminal and chassis, and between the DG coil terminal and chassis.

The cut-off current should be 20mA.

2.5.1.2

Grounding conductivity check

Check that the resistance value is 100ohms or less when 25A is passed between the AC input

terminal grounding GND and chassis GND.

2.5.1.3

Degaussing coil operation

Confirm that when OSM DEGAUSS is executed, the picture vibrates and then stops.

2.5.1.4

IPM OFF MODE function operation (Set the AC power input to 230V)

Use the full white pattern without R, G, B signals.

Select IPM OFF MODE from OSM, and set to 1:ENABLE.

(1) IPM OFF MODE ENABLE

(a) Confirm that when R, G, B, H/V SYNC signals are removed, the system waits for

approx. five seconds, displays IPM OFF MODE for approx. three seconds, and then the

picture dark ens.

Also confirm that Power Indicator changes to orange and the power consumption is

as follows.

(b) Confirm that when R, G, B, H/V SYNC signals are input again, the high voltage is

rcovered, and the picture appears in approx. five seconds.

Adjustment item

Inspections

Adjustment mode/set

Normal mode

Imput signal/pattern

Status

indicator

Confirmation timing

Timing No. 12 (106.25kHz / 85Hz, 1600x1200)

Power consumption

3W or less

Summary of Contents for DPro2070SB

Page 22: ...1 15 Fig 7 The principle of DDCC compensation ...

Page 23: ...1 16 Fig 8 a DDCC adjustment item ...

Page 24: ...1 17 Fig 8 b DDCC adjustment item ...

Page 25: ...1 18 Fig 9 DDCC circuit diagram ...

Page 103: ...4 Wave form 1 POWER 2 CONTROL MAIN 3 DEFL MAIN 4 DEFL SUB COIL DRIVE MAIN 5 VIDEO ...