2201Q4JE-MY-C9-N_2018.01.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 4032**C

2.5

Mechanisms

2-12

2.5.6 Capacity Control Mechanism

The capacity control mechanism, by moving a slide valve, lets suction gas (immediately before

compressed) bypass and advance to the suction side, to help shorten the rotor portion used for

compression. The slide valve is located at the bottom of the casing in which the rotors mesh together,

and is constructed to move parallel to the rotor shaft. This movement is changed by a cam mechanism

into rotation movement. Its position (namely, capacity control ratio) is indicated externally and, at the

same time, fed back to the automatic control circuit by changing the electric resistance.

4032 ** C compressor, has a capacity control mechanism

for reducing start-up load on the high-stage

,

and a capacity control mechanism for

coping with load change on the low-stage

.

Figure 2-9 Capacity Control Mechanism

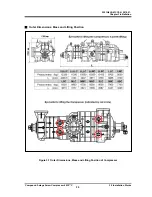

2.5.7 Bearing and Balance Piston

For the load acting on the rotor perpendicular to the shaft, sleeve-type white metal-lined bearing is used.

For the load acting along the shaft direction, the

low-stage compressor uses tilting pad bearings while

the high-stage compressor uses angular ball bearings in the front combination.

In case of API 619 compliance is required and/or special gas component is contained in the working

fluid, the high-stage compressor also uses tilting pad bearings for the load acting along the shaft

direction.

Special care is taken to cope with the load acting along the shaft direction. Because the M rotor is a

kind of helical gear and also because the thrust force produced by discharge pressure is larger than

that for F rotor, the load applied onto the M rotor is reduced by using not only a thrust bearing but also a

balance piston that applies pressure from the opposing direction.

2.5.8 Shaft Seal

A mechanical seal assembly, which has balance type double seal structure is used as a shaft seal.

A mechanical seal assembly has two sliding seal blocks consisting of rotating rings and stationary rings

on inner machine side and atmosphere side. Those sliding seal blocks prevent leakage of working fluid

(refrigerant) and oil from M rotor shaft.

For example, the BBDE (Balance Bellow Double Seal) which is currently used as standard seal,

employs stationary ring (mating ring) made from carbon, rotating ring made from SiC, and O-rings for

the packing.

Figure 2-10 Slide Valve in the

Rotor Casing