2201Q4JE-MY-C9-N_2018.01.

Chapter 1 Safety

Compound 2-stage Screw Compressor 4032**C

1.3

Residual Risks

1-4

1.3

Residual Risks

The following information assumes that this product is operated or inspected/maintained while being

used in general refrigerating/cold storage/gas compression package units.

Note that all hazardous sources cannot be predicted for the applications mentioned.

Devise appropriate countermeasures for hazardous sources in your systems.

Table 1-2 Hazardous Sources

Hazardous sources

Predicted hazard

Countermeasures in

operation

Countermeasures in

cleaning, inspecting,

and replacing parts

A

Motor and

compressor coupling

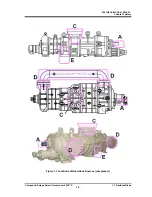

Refer to Figure 1-1

Caught in due to contact

Install coupling cover

and prohibit opening.

Keep away.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

B

Motor terminals

Electric shock caused by

contact with live wires or

electrical leakage

Keep away.

Do not open terminal

boxes.

Do not touch terminal

boxes.

Turn off motor main

power and control

power, and conduct

lockout/tagout.

C

Compressor

low-stage side

suction casing

Refer to Figure 1-1

Frostbite due to contact

Contact with or inhalation of

hazardous substances

generated by leakage of

refrigerant or the like

Keep away and do not

touch.

Wear protective gear.

Detect gas leakage.

Wear protective gear.

Work under room

temperature.

D Compressor

intermediate piping

(low-stage discharge

port to high stage

suction port)

Refer to Figure 1-1

Burn injury due to contact

Contact with or inhalation of

hazardous substances

generated by leakage or spout

of refrigerant or the like

Keep away and do not

touch

Wear protective gear

Gas leakage detection

Wear protective gear

Work in temperatures

below 40 °C

E

Compressor

high-stage side

discharge casing and

discharge piping

Refer to Figure 1-1

Burn injury due to contact

Contact with or inhalation of

hazardous substances

generated by leakage or spout

of refrigerant or the like

Keep away and do not

touch.

Wear protective gear.

Detect gas leakage.

Wear protective gear.

Work at a temperature

of not higher than

40

°

C.

F

Check valves/service

valves and joints on

each section of the

package unit

Contact with or inhalation of

hazardous substances

generated by mishandling or

leakage

Frostbite or burn due to contact

Sufficient ventilation

Indicate valve

open/close state.

Keep away and do not

touch.

Wear protective gear.

Sufficient ventilation

Wear protective gear.

Tagout for controlled

valve

G

Solenoid valves/

electric valves on

each section of the

package unit

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact with

driving part

Install protective cover

on terminals, and

prohibit opening.

Keep away and do not

touch.

Wear protective gear.

Turn off each breaker

and the control power,

and conduct

lockout/tagout.

Wear protective gear.

H

Electric components

in each section of the

package unit (oil

heater, protective

switch, etc.)

Electric shock caused by

contact with live wires or

electrical leakage

Pinched due to contact with

driving part

Install protective cover

on terminals, and

prohibit opening.

Keep away and do not

touch.

Wear protective gear.

Turn off each breaker

and the control power,

and conduct

lockout/tagout.

Wear protective gear.

I

Package unit oil

drains

Contact with hazardous

substances generated by

leakage or spout

Burn caused by contact with

high-temperature fluid

Sufficient ventilation

Keep away and do not

touch.

Wear protective gear.

Sufficient ventilation

Wear protective gear.

Work at a temperature

of not higher than

40

°

C.

J

Noises

Damage caused by noise

Wear protective gear.

—