2201Q4JE-MY-C9-N_2018.01.

Chapter 2 Compressor Specifications and Structure

Compound 2-stage Screw Compressor 4032**C

2.4

Compressor Structure

2-8

2.4

Compressor Structure

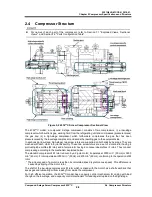

For names of each part of the compressor, refer to Section 7.1 "Exploded Views, Sectional

Views ", and Section 7.2 "Parts Configuration Table".

Figure 2-2 4032**C Screw Compressor Sectional View

The 4032**C model, a compound 2-stage compressor, consists of two compressors, (i) a low-stage

compressor which suctions gas, working fluid, from the refrigerating unit and compresses (pressure-raises)

the gas and (ii) a high-stage compressor which furthermore compresses the gas that has been

pressure-raised by the low-stage compressor and sends the resulting gas to the equipment side.

In each casing (low-stage, high-stage), two screw rotors are supported on both ends by bearings. They are

meshed with each other in a joint assembly. These two screw rotors are a set of a male rotor having 4

protruding lobe profiles (M rotor) and a female rotor having 6 concave lobe profiles (F rotor). They conduct

compressing according to the mechanism explained below.

The standard compressor's M rotor is driven by a 2-pole motor; it operates at 3000 min

-1

(50 Hz) or 3600

min

-1

(60 Hz). F rotor operates at 2000 min

-1

(50 Hz) or 2400 min

-1

(60 Hz), conforming to the operation of M

rotor.

* The actual speed of a motor is less than its calculated speed (synchronous speed). This difference is

caused by slipping of the motor rotor.

The shaft of the low-stage compressor's M rotor which is linked with the motor has a shaft seal block that

keeps gas and lubricating oil from leaking from inside the compressor.

For high efficient operation, the 4032**C model has a capacity control mechanism for coping with load

change on the low-stage, and a capacity control mechanism for reducing startup load on the high-stage.