2201Q4JE-MY-C9-N_2018.01.

Chapter 4 Compressor and Package Unit Operation

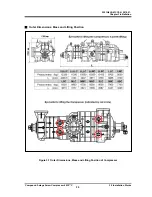

Compound 2-stage Screw Compressor 4032**C

4.1 Lubricating Oil (Refrigerant Oil)

4-2

Lubricating oil contains various additives to fulfill necessary lubricating conditions. Types of

additives and their mixing ratio depend on each oil brand. We, therefore, recommend to avoid

mixed use of different brands of lubricating oil. If mixed brands of lubricating oil are used, the

different additives in the lubricating oil may react with each other and produce foreign

substances like slurry.

If it is necessary to change the brand of lubricating oil, collect as much as oil as possible from

the compressor as well as from the condenser, evaporator, and all other refrigerating unit

components before charging the new lubricating oil. After 100 to 200 hours of operation, replace

the oil again.

If lubricating oil manufacturers differ, contact both of them and inquire whether the changing is

appropriate. The same confirmation is required for changing the brand even if it is of the same

manufacturer.

There is no problem in changing the viscosity level within the same brand. However, make sure

that the viscosity grade will not cause problems during operation. (Example

:

SUNISO

3GS

→

SUNISO 4GS)

4.1.3 Precautions for Handling lubricating oil

When refilling lubricating oil, ensure that it is clean and does not contain foreign matters.

Be careful that air and water are not mixed in when refilling.

To ensure that the lubricating oil does not absorb air moisture, keep it indoors in an airtight

container until use.

4.1.3.1 Precautions for Handling Polyalkylene Glycol (PAG)

PAG oil is much more hygroscopic than mineral oils and any moisture mixed in the oil may lead to rust,

corrosion and wear within the package. When handling PAG oil, pay special attention to the following

points.

Do not perform oil charging in rainy weather or at a place with high humidity to prevent

absorbing moisture.

Before charging, remove as much moisture as possible from the system by exhausting it with

a vacuum pump for a sufficient length of time and leaving the system in vacuum condition

overnight.

Do not open the lid of pail (oil container) until just before charging. Once the can is opened,

finish the oil charge as quickly as possible. (Finish the charge of a single can of oil within 15

minutes.)

Cover any gaps between the pail opening and the charge hose so that foreign substances or

moisture cannot enter. A more effective way is to substitute any space inside the pail with

nitrogen gas .

Always charge all oil from the pail. Even if some oil remains, do not use it subsequently.

If any oil drops on a painted surface, wipe it away as soon as possible. Otherwise the paint

may come off.

4.1.3.2 Precautions for Handling Polyolester (POE) Oil

This type of oil has high hygroscopicity as polyalkylene glycol, and also exhibits hydrolyzability under

high temperature environments. Moisture entry must be avoided. Therefore, special attention must be

paid as with PAG when handling POE.

Finish the charging in as short a time as possible after opening the pail to minimize exposure

to air.

Make sure that all oil in a pail is used in a single charging. Any remaining oil must be stored

indoors with the can lid closed tightly. Do not attempt to store it for a long time.

Because POE can hydrolyze, make sure to perform an oil analysis regularly in the package to

see if any abnormal conditions are present.