55

EN

M1.1.HB250CF.NLFREN - 05012018

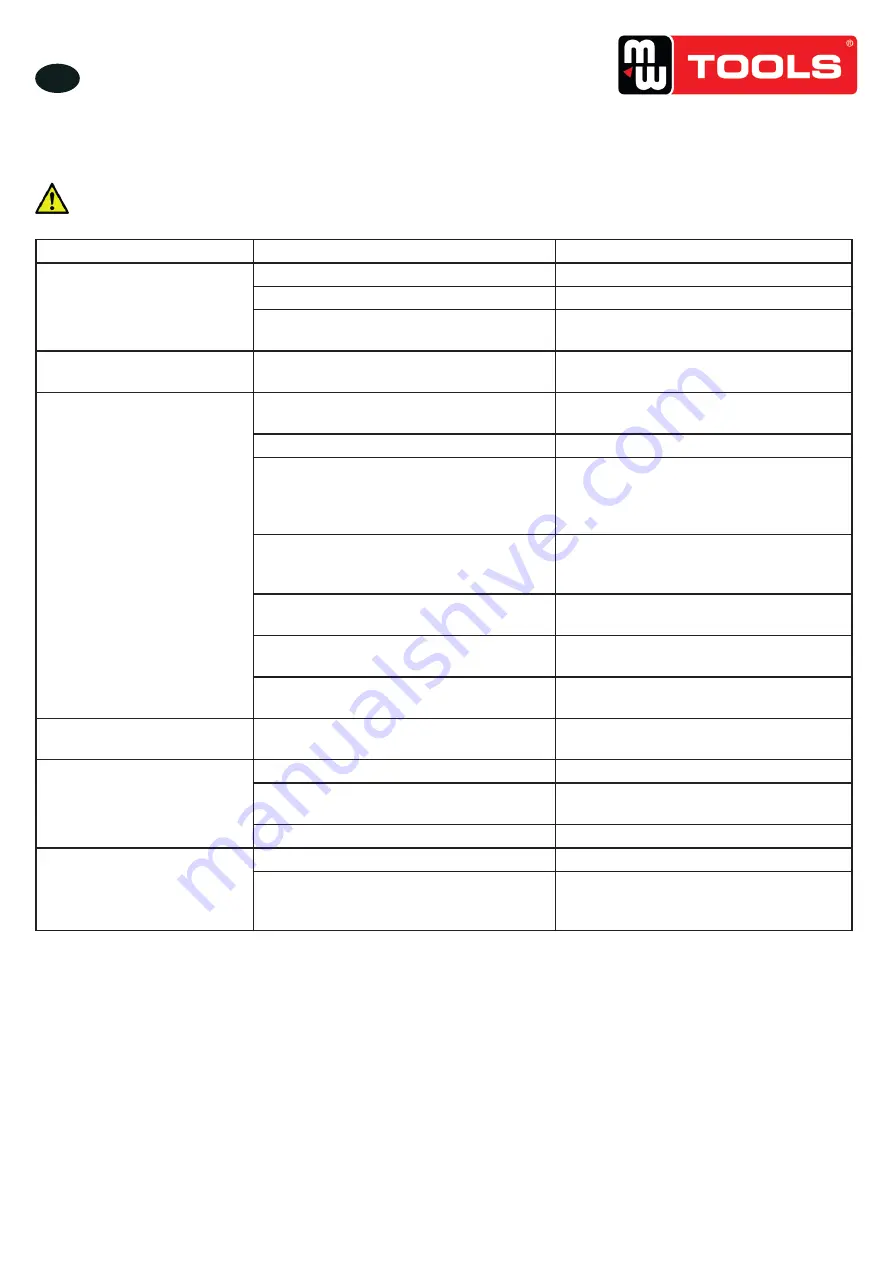

10 Trouble shooting

Skilled personnel only is allowed to perform the operations�

Failure phenomena

Cause and phenomena

Resolutions

The motor does not run in lifting

operation.

Power supply is abnormal

Check and correct wire connection

There is a short circuit in the AC contactor

Check the wire of AC contactor

The limit switch is broken

Check the limit switch, wires and adjust or

replace the limit switch

The motor has noise but can

not run

Motor phase loss

Stop run the motor and check the wire

In lifting operation, the motor

runs, but there is no lifting

movement

The motor turns reverse

Change the phases of the power supply

wires

The amount of hydraulic oil is not enough

Add hydraulic oil

There is some air in the pump due to the

transport, causing the air block-up

Dismount the one-way valve and raise the

lift a little (pay attention to the oil). Mount

the one-way valve if the oil outflows from

the hole

Throttle valve is out of order

Check the valve element and seal rings of

throttle valve, clean the valve element and

replace the seal rings

Some block in the valve element of oil

returns solenoid valve

Clean the valve element

Seal rings in the oil pump outlet are

damaged

Demount the gear pump and replace the

seal rings

Motor runs heavily. Out net of oil filter blocks

seriously

Clean the oil filter

The lift raises slowly

Seal rings in the oil pump outlet are

damaged

Demount the gear pump and replace the

seal rings

The lift trembles in the lifting

operation

There is some air in the hydraulic oil circuit

Raise the lift up and down to exhaust the air

Air leakage on the upper connector of

absorbing oil hose

Check the absorbing oil hose of oil pump

The oil filter blocks

Clean the oil filter

The lift can be raised but can

not fall

The button is out of order

Replace the button

The safety claw is not separated from the

safety plate

Check the electromagnet, replace it if

damaged. If not, adjust the safety to make

it normal

copyrighted

document

- all

rights

reserved

by

FBC