43

EN

M1.1.HB250CF.NLFREN - 05012018

The centre-of-gravity position of each kind of vehicle is different. First know about the centre-of-gravity of vehicles. Make the

centre-of-gravity close to the plane formed by the two columns when the vehicle drive into the lift. Adjust the lifting arm, make

the bearing point support the bearing surface of vehicles.

4 Safety instructions

4�1 General precautions

• Workers should read the instruction manual carefully before carrying out any operation with the lift.

• The manufacturer is not liable for any injury to persons or damage to vehicles and other property caused by the incorrect

and unauthorized use of the lifts.

•

The operator and the maintenance fitter are required to observe the prescriptions of safety regulation in force in the country

of installation of the lift.

•

Furthermore, the operator and maintenance fitter must:

- Always work in the stations specified and illustrated in this manual;

- Never remove or deactivate the guards and mechanical, electrical, or other types of safety devices;

- Read the safety notices placed on the machine and the safety information in this manual.

In the manual all safety notices are shown as follows:

Warning:

Indicates following operations that are unsafe and can cause minor injury to persons and damage the lift, the vehicle or

other property.

Risk of electric shock:

A specific safety notice placed on the lift in areas where the risk of electric shock is particularly high.

4�2 Protection devices

The safety protection devices use to protect the operator in case of overload or machinery failure:

•

In the case of overload, the overflow valve of the pump will open, the hydraulic oil will return to the oil tank.

• The mechanical safety device works automatically to prevent the carriage from falling off when the oil cylinder looses

pressure.

U

U

S

S

E

E

R

R

’

’

S

S

M

M

A

A

N

N

U

U

A

A

L

L

- 9 -

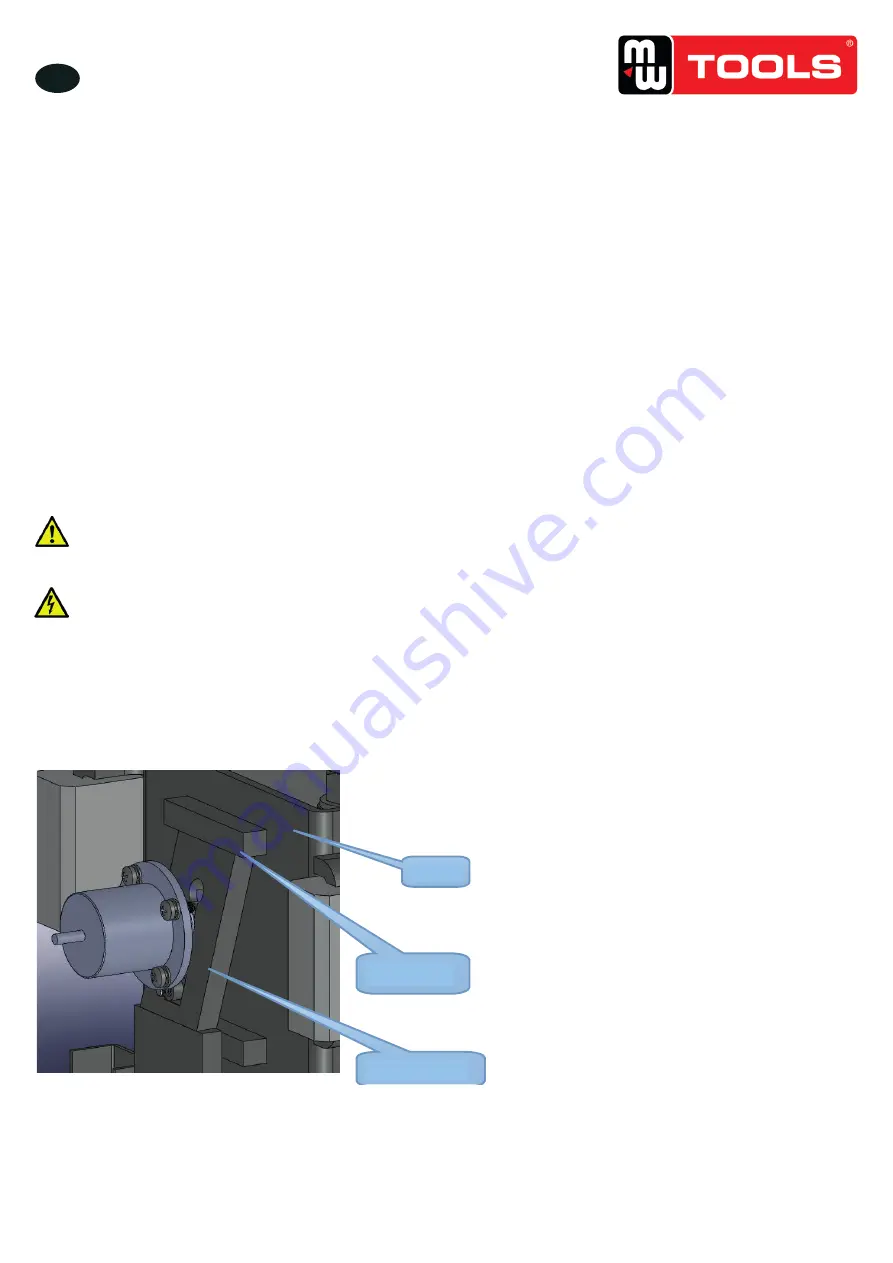

-Operators will hear the sound when the insurance claw falls on the insurance strip in the case of normal use. If

not, this machine is prohibited to use. Operator can check the insurance device by opening the decorated box. If

the insurance device is blocked, adjust the screw on the insurance claw till the sound can be heard when the

insurance claw falls on the insurance strip.

-Only press

“

LOCK

”

button after the machine is lifted, vehicle maintenance can be permitted.

-If the two carriages are not in the same plane, adjust the nut on steel cable to keep them in the same plane.

Tighten the steel cable, or the two carriages can not be synchronous.

-Locking devices are installed in each lifting arm, it can lock automatically when lifting arm rotate to any needed

angle. When the carriage in the lowest position, the lifting arm can rotates freely. In order to prevent the lifting

tray from falling, we adopt the adjustable thread lifting tray to make it more safe and convenient

Risk for extrusion

During up and down operations, personnel leave the said area without following the rule and instruction.

During up and down operations, no person is admitted to work beneath the movable parts of the lift, should work

in the safe zone.

Risk of impact

Before the operator begins up and down movements, make sure that there are no personnel inside the danger

zone. When, due to operational reasons, the lift is stopped at relatively low elevations (lower than 1.75m above

the ground) personnel must be careful to avoid impact with parts of the machine not marked with special colors.

Risk of falling (vehicle)

This hazard may arise in the case of incorrect positioning of the vehicle on the lifting arms, overweight of the

vehicle, or in the case of vehicles of dimensions that are not compatible with the capacity of the lift.

When the lifting arm is being tested, the vehicle engine can not be turned on.

There is nothing should be placed on the lift-lowering area and the movable parts of the lift.

Risk of slipping

The floor caused by lubricant contamination of around the lift. The area beneath and immediately surrounding

the lift and also the platforms must be kept clean. Remove any oil spills immediately.(

Picture 14

)

Risk of electric shock

Risk of electric shock in areas of insulated and shattered electric equipments

Do not use jets of water, steam solvents or paint next to the lift, and take special care to keep such substances

colum

n

Insurance

claw

Insurance strip

Picture 4

Picture 3

Safety device

Safety strip

Column

copyrighted

document

- all

rights

reserved

by

FBC