Rockhopper II series printers – Maintenance Manual

296

AP-74065, Rev. 1.2, 27/09/04

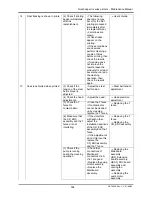

9.3.2. Problems relating to paper feed

No. Phenomenon

Check point

Action

Refer to

1

The paper comes off at paper

set initialization or during the

printing operation.

(1) Check if the

P_REAR sensor

assembly and

P_EDGE sensor

assembly are

operating correctly

via “Test: Sensor” of

the self-diagnostic

function

• Check if the

connections of the

following

connectors.

• Mainboard

assembly :

J128/J129, J137-

J152

• CR board : J201-

J261

• Adjust the

sensitivity of the

P_EDGE sensor

• Replace the

P_REAR sensor

assembly and

P_EDGE sensor

assembly

→

Replacing the

Mainboard

assembly,

HDD_Extension

board assembly,

HEAD_DRV board

assembly and

cooling fan

assembly.

→

Replacing the CR

board assembly

→

media sensor

sensitivity

adjustment

→

Replacing the

P_REAR_R sensor

and P_REAR_L

sensor assembly

→

Replacing the

P_EDGE sensor

assembly.

2

The paper is fed askew or

meanderingly at paper set

initialization or during the

printing operation.

(2) Check the platen

for contamination by

paper dust and ink.

• If the platen is

contaminated by ink

or paper dust, wipe

off with a damped

soft cloth.

→

User’s Guide

3

The paper is wrinkled at paper

set initialization or during the

printing operation.

(3) Check the

rotation of pressure

roller with the

pressure arm at the

raised position.

• If the surrounding

area of the pressure

roller is

contaminated by

paper dust and

waste paper, wipe

off with a damped

soft cloth.

→

User’s Guide

4

The paper jams up at paper set

initialization or during the

printing operation.

(4) Check paper

guide F for

significant

deformation, flaws,

foreign material, etc.

• If foreign materials

such as wastepaper

are found on the

paper guide F,

remove them.

• Replace the paper

guide F.

→

Removing media

guide F.

5

After the paper set initialization,

the paper size is detected

incorrectly.

(5) Is the flange

properly installed?

• Securely insert

flanges into the

paper tube for the

roll paper.

→

User’s Guide

(6) Check the rollers

of the paper

receiver for flaws

and wear that may

hinder the rotation

of the scroller.

• Replace the rollers

of the scroller.

→

Replacing the

scroller R assembly.

→

Replacing the

scroller L assembly.

(7)

Check

the

scrollers for bends.

• Replace the

scrollers.

→

User’s Guide

Summary of Contents for Rockhopper II 2H

Page 1: ...Maintenance Manual MUTOH EUROPE N V AP 74065 Rev 1 2 27 09 2004 ...

Page 3: ...Rockhopper II series printers Maintenance Manual 4 AP 74065 Rev 1 2 27 09 04 ...

Page 5: ...Rockhopper II series printers Maintenance Manual 6 AP 74065 Rev 1 2 27 09 04 ...

Page 7: ...Rockhopper II series printers Maintenance Manual 8 AP 74065 Rev 1 2 27 09 04 ...

Page 13: ...Rockhopper II series printers Maintenance Manual 14 AP 74065 Rev 1 2 27 09 04 ...

Page 29: ...Rockhopper II series printers Maintenance Manual 30 AP 74065 Rev 1 2 27 09 04 ...

Page 201: ...Rockhopper II series printers Maintenance Manual 202 AP 74065 Rev 1 2 27 09 04 ...

Page 255: ...Rockhopper II series printers Maintenance Manual 256 AP 74065 Rev 1 2 27 09 04 ...

Page 318: ...Rockhopper II series printers Maintenance Manual 319 AP 74065 Rev 1 2 27 09 04 ...