Page 511

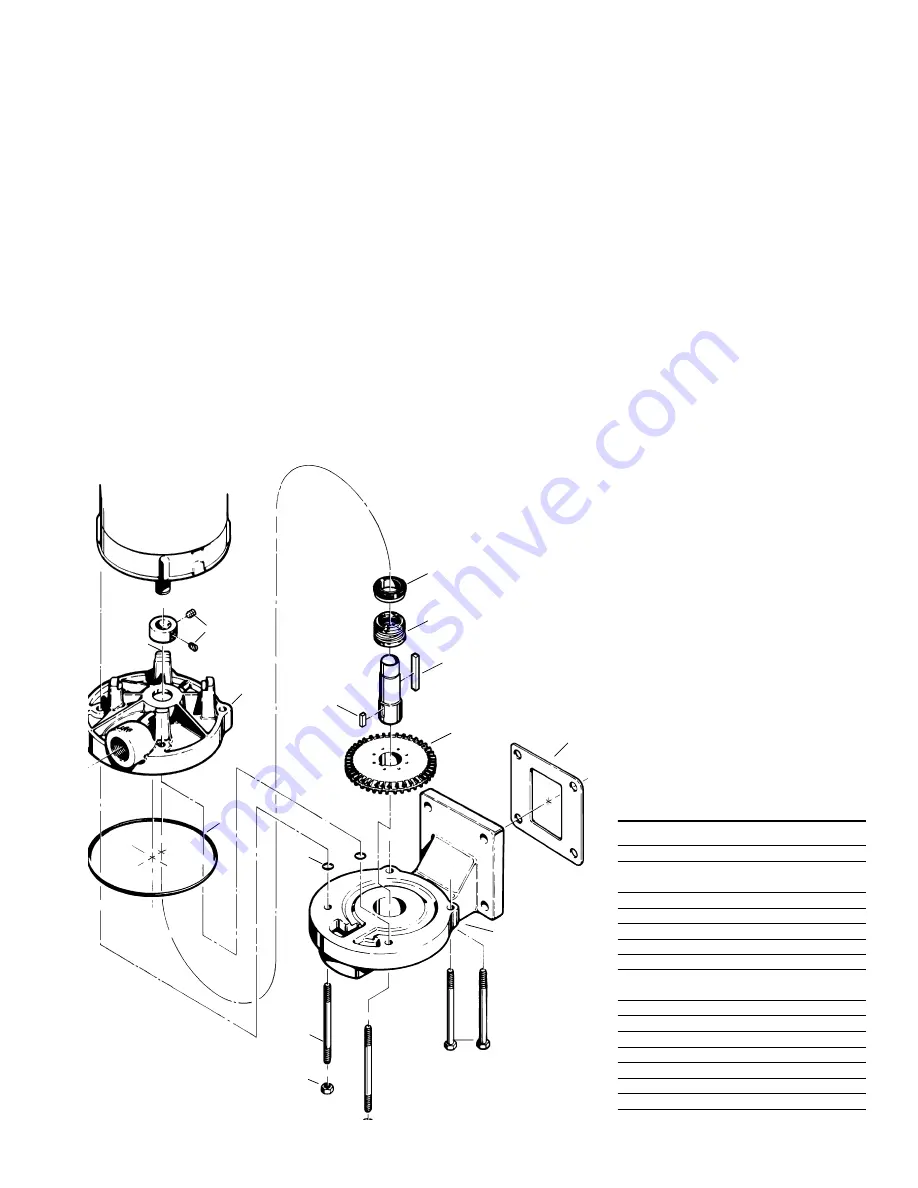

Figure 4-5

C3 VERTICAL FLANGE MOUNT PUMP

carefully inspect for microscopic

cracks and nicks. Scratches that

might be ignored elsewhere can

produce leakage if they are on seal

carbons and seat wearing surfaces.

Cleanliness is imperative when

working with mechanical seals.

Almost unnoticeable particles

between seal faces can be, and

often are, the cause of early seal

failures.

Check the impellers, they are

designed to float. They should

move easily on the shaft. As long

as they can be moved on the shaft

by hand, they are loose enough. If

the impeller can be rocked or

wobbled, it is too loose and must be

replaced.

Check the sleeve or shaft for

galling, pitting, and corrosion. If the

shaft or sleeve is corroded where

the seal comes in contact with

them, the shaft or sleeve must be

replaced. Surface corrosion must

be removed so that seals can slide

freely during assembly. The shaft

diameter should be no smaller than

.002" below the nominal fractional

seal sizes. Remove any nicks or

burrs which may have occurred

during disassembly. Reclean parts

as necessary.

4E Reassembly (C3 and P3)

All parts should be visually inspect-

ed and cleaned or replaced as

outlined in 4D above.

1. The seal seat (#125) must be

installed in the motor bracket

before the bracket is installed on

the motor. To install the seat:

a. Place the motor bracket face

up on a flat surface.

15

14

1

7

125

12

23

11

23A

60

19

2

18

20

b. Carefully press the seat,

smooth side up, into the seat

cavity of the motor bracket.

To make the installation of the

seat easier, apply a thin

coating of compatible lubricant

to the elastomer portion of the

seat prior to installation. Care

must be taken not to damage

the seat face. Thumb

pressure is usually sufficient

to install the seat.

2. Install the motor bracket.

a. Make sure the locking collar is

positioned on the motor shaft.

b. While holding the motor

bracket with the outlet port

facing up, slide the bracket

over the two (2) studs on the

motor face.

c. Slide the bracket back until

the feet are resting against the

motor face. Light tapping may

be necessary to seat the

motor bracket in the proper

position.

d. Install the four (4) “O” rings

(#8) on the two studs. This

will help hold the bracket in

place during the remainder of

the assembly operation.

NAME/DESCRIPTION

PART NO.

QTY.

Motor Bracket

1

1

Cover/Vertical

2

1

"O" Ring/Casing

7

1

"O" Ring/Guide Rod

8

4

Impeller

11

1

Seal Rotating Element

12

1

Seal Stationary Seat

125

1

Lock Collar/Sleeve

14

1

Setscrew/Lock Collar

15

2

Shaft Sleeve

17

1

Guide Rod

18

2

ThruBolt

19

2

Nut

20

2

Pipe Plug/Drain

22

1

Key/Impeller Drive

23

1

Key/Sleeve Drive

23A

1

Gasket

60

1

8

C3