Page 515

4A Preliminary (P3 and P15)

1. Disconnect the inlet and outlet-

piping before unbolting the

pump. If the pipes are corroded,

use penetrating oil on the

threads to aid in removal.

2. Unbolt the pump from the base

and remove. Disassembly

instructions for the pump are

found in section 4, T51 PUMP

ENDS. All work on the unit

should be performed on an

elevated workbench whenever

possible.

The disassembly and reassembly

procedures are broken into two

sections covering the following

units:

4B — Disassembly of the P3 and

P15 Bearing Pedestals

4D — Reassembly of the P3 and

P15 Bearing Pedestals

Exploded views of each unit,

Figures 4-19 and 4-20 are provided

for referencing the numbers in the

following procedures, i.e. flinger

(#21).

4B Disassembly (P3 and P15)

The following tools and equipment

are needed for disassembly of the

P3 and P15 units:

4.

1. Soft plastic or wooden mallet.

2. Arbor press or vise.

3. 3/4" X 6" piece of water pipe for

P3, 1-1/4" X 6" for P15.

4. Internal snap ring plier.

5. Penetrating oil.

When installing or removing

bearings from the shaft, the use of

an arbor press is strongly recom-

mended.

To disassemble the pedestal:

Refer to Figures 4-19 and 4-20 for

reference to the numbered parts in

the procedures below.

1. Remove the flinger (#21) located

in the pump end of the bearing

pedestal (#3).

2. Using a snap ring plier, remove

snap ring (#4).

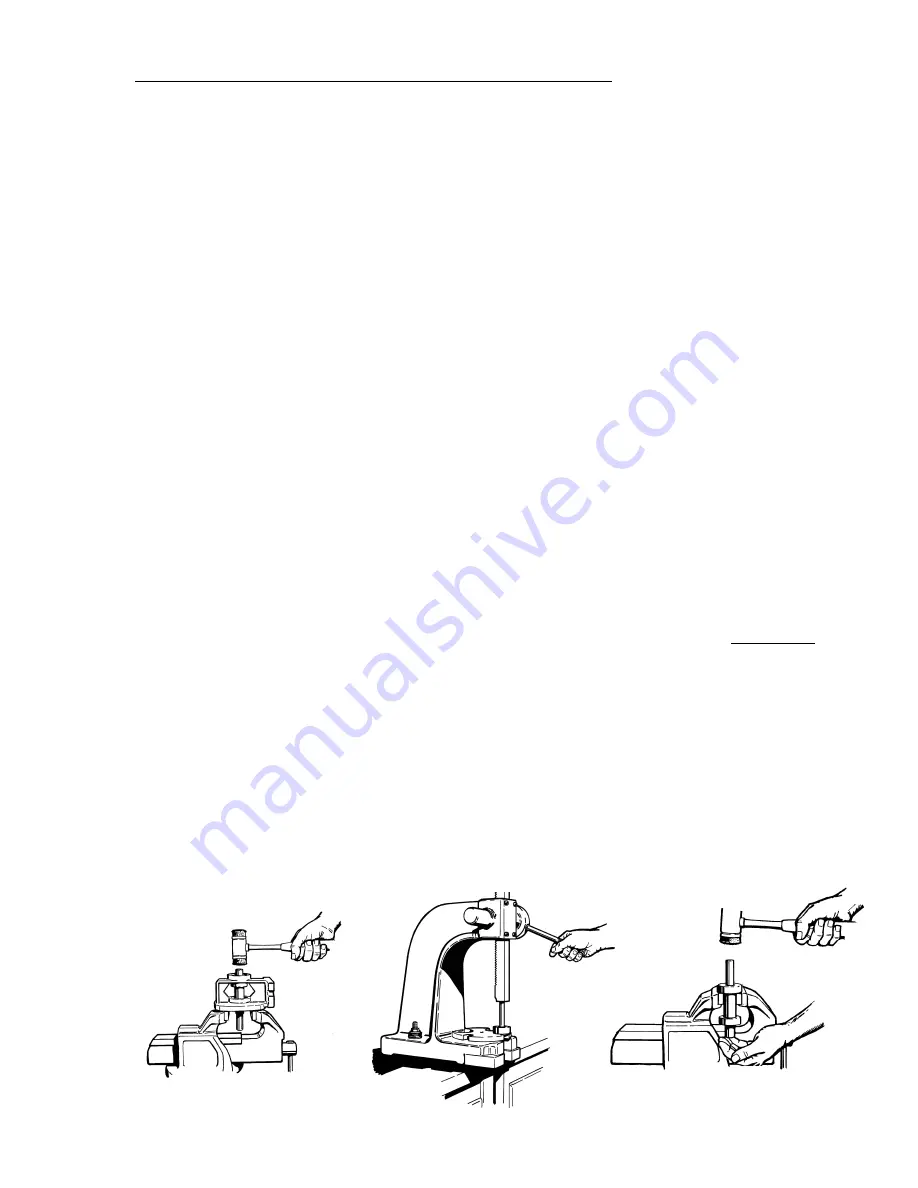

3. Open the jaws of the vice

approximately 2-1/4" for model

P3 and 3" for model P15.

4. Place the pedestal, pump side

down, on the jaws. Refer to

Figure 4-18.

5. Using a plastic or wooden mallet,

gently tap on the end of the shaft

until it slides out of the frame.

Both bearings should come out

with the shaft. Do not use a

metal hammer; severe damage

to the shaft will occur.

6. Using the arbor press remove

the two (2) bearings from the

shaft. Refer to Figure 4-21. If the

inner race is well supported

during this operation, no damage

will be done to the bearings.

If an arbor press is not available, a

bench vise may be substituted

using the following instructions.

1. Remove the pedestal and close

the jaws to approximately 1-1/8"

for model P3 and 1-3/8" for

model P15.

2. Place the shaft with either

bearing resting on top of the jaws

and gently tap on the end of the

shaft until the bearing is re-

moved. Refer to Figure 4-22.

3. Repeat step 2 to remove the

other bearing. Good support

used on the inner races will

prevent bearing damage.

4C Inspection of Components

Thoroughly clean all parts. All

components should be examined

for wear and corrosion. Replace

any parts showing visible wear.

Check to be certain that a press fit

still exists between the shaft and

the bearings. New bearings, or at

least cleaned and regreased

bearings, are recommended.

Check the shaft for galling, pitting,

and corrosion. Surface corrosion

on the pump portion of the shaft

must be removed so the seals will

slide freely during assembly. The

shaft diameter should be no smaller

than .002" below the nominal

fractional seal sizes. Remove any

nicks or burrs which may have

occurred during disassembly.

Reclean parts as necessary.

Figure 4-22

Figure 4-18

Figure 4-21

A. Preliminary

B. Disassembly

C. Inspection of Components

D. Reassembly

E. Testing and Final Adjustments

BEARING PEDESTALS

Service

T51 SERIES