114

Chapter 7

535-PROF User's Manual

Applications

temperature sensor

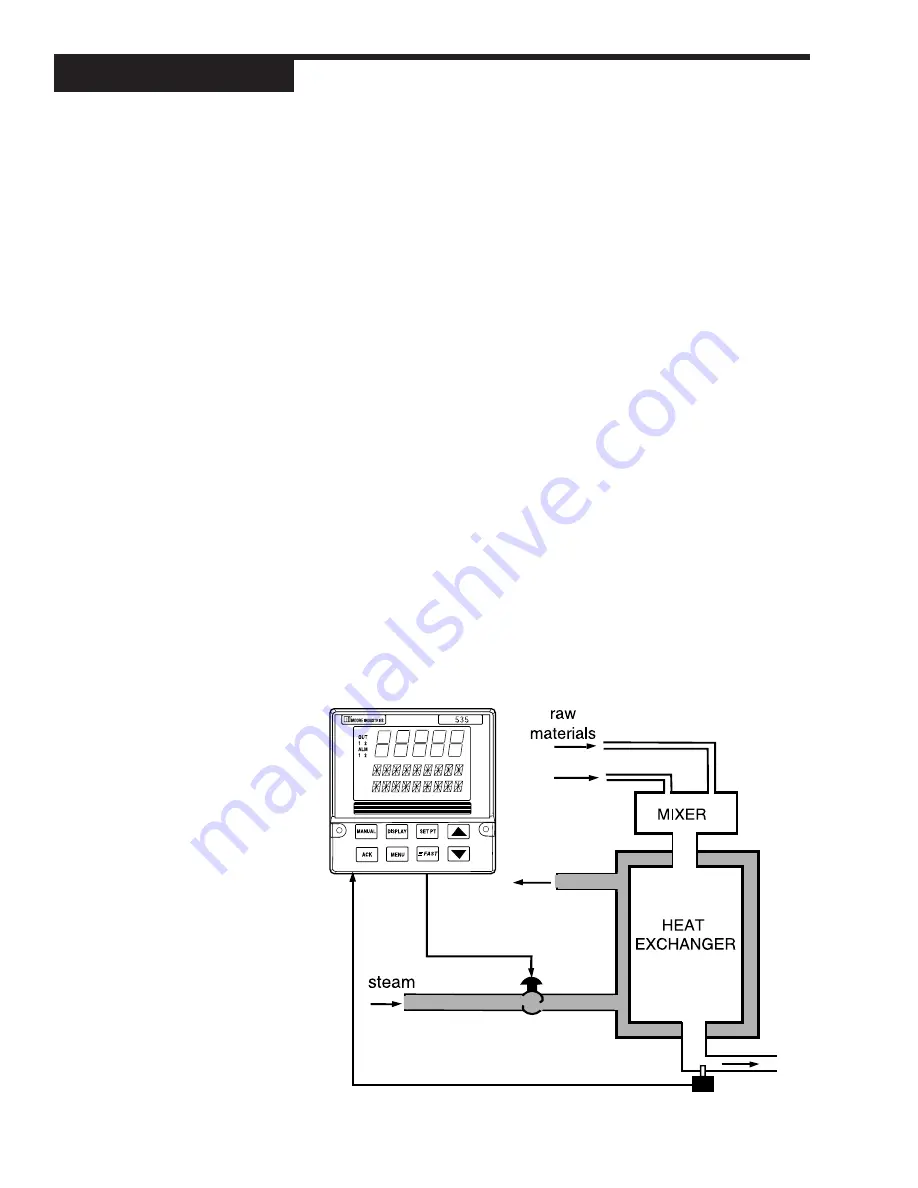

Figure 7.20

Heat Exchanger Control Loop for

Steam Supply

7. Use

SHED OUT

to specify an output level if the unit sheds and trips to manual

control.

8. To specify a control setpoint (in case the host is supervising the setpoint) if

the 535 sheds.; Set

SHED SP

to DESIG. SP and then, set the parameter

DESIG. SP

to the desired setpoint.

V. CASCADE CONTROL

While a single 535 Controller is effective in maintaining many control systems,

others require more sophisticated control schemes.

Figure 7.19, shows a sample

control set up with a 535 controller. Cascade control is often used to control a

process more precisely. In cascade control, a second variable is monitored in

addition to the primary controlled variable. This second variable is one that more

quickly reflects any changes in the process environment.

Cascade control involves installing one feedback loop within another, as in

Figure

7.20. This second loop, based on steam pressure, is called the inner or secondary

feedback loop. The outer or primary feedback loop is based on the temperature

of the liquid in the heat exchanger. However, instead of directly positioning the

steam valve, the output of the primary 535 controller is now used to adjust the

setpoint of the secondary 535 controller, which then positions the valve.

Cascade Control is typically used for the following:

• A slow responding process with a significant lag time

• A process requiring more advanced or tighter control

• A process where two PID control loops need to interact to achieve optimum

control. Cascade control is commonly implemented in temperature control

applications where the main control variable is affected by another variable,

i.e., pressure.

Example