58

OM

AGSB-5

7. Vent the air from the evaporator water side as well as from the system piping. Open all

water flow valves and start the chilled water pump. Check all piping for leaks and

recheck for air in the system. Verify the correct flow rate by taking the pressure drop

across the evaporator and checking the pressure drop curves in the installation manual,

IMM AGS.

Evaporator Freeze Protection

Flooded evaporators are popular with chiller manufacturers because of their inherent high

efficiency. Care must be exercised in the equipment design and in the operation of these

evaporators to prevent freezing between 32

°

F and -20

°

F.

For protection down to 0

°

F (-18

°

C), the AGS chillers are equipped with thermostatically

controlled evaporator heaters that help protect against freeze-up provided the chiller goes

through its normal pumpdown cycle. Several occurrences can prevent this normal

pumpdown from happening:

1. A power failure will prevent pumpdown and there is a potential for freezing outdoor

equipment in systems using 100 percent water as the chilled fluid.

2. Unit shutdown due to a fault will cause immediate compressor shutdown without the

pumpdown cycle. This situation can be remedied by correcting the fault, restarting the

unit, and allowing it to go through its normal shutdown pumpdown.

CAUTION

:

The heaters come from the factory connected to the control power circuit. The

control power can be rewired to a separate 115V supply (do not wire directly to the

heater). If this is done, the disconnect switch should be clearly marked to avoid

accidental deactivation of the heater during freezing temperatures. Exposed chilled

water piping also requires freeze protection.

DANGER

If more than one power source connects to the unit, each must be clearly marked that

there are additional power sources to the unit, and the unit must have a notice that

there are multiple power sources to it.

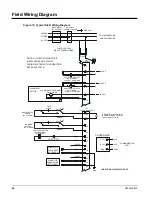

It is required that the chilled water pump’s starter be wired to, and controlled by, the chiller's

microprocessor. The controller will energize the pump whenever at least one circuit on the

chiller is

enabled

to run, whether there is a call for cooling or not. The pump will also be

energized when the controller senses a near-freezing temperature at the chiller outlet sensor

to assist in cold weather freeze protection. Connection points are shown in Figure 12 on

page 64.

For additional protection to -20

°

F (-29

°

C) and to protect against the consequences described

above, it is recommended that at least one of the following procedures be used during

periods of sub-freezing temperatures:

1.

Addition of a concentration of a glycol anti-freeze with a freeze point 15 degrees below

the lowest expected temperature. This will result in decreased capacity and increased

pressure drop.

Note:

Do not use automotive grade antifreezes as they contain inhibitors harmful to

chilled water systems. Only use glycols specifically designated for use in building

cooling systems.

Summary of Contents for AGS 206A

Page 65: ......